PRODUCTS

CONTACT US

SZP series slurry pump is a new type of high-efficiency energy-saving anti-wear pump, suitable for electric power, metallurgy, coal, building materials and other industries. The series of slurry pump in the hydraulic design, structural design has innovation, flow components using self-developed anti-strong wear-resistant alloy cast iron manufacturing. It has the remarkable characteristics of high efficiency, energy saving, long service life, light weight, reasonable structure, reliable movement, low vibration, low noise, and convenient maintenance.

SAZP ceramic slurry pump series is suitable for conveying corrosive and abrasive slurry containing solid particles in mining, metallurgy, electric power, coal, chemical industry, building materials and other industries, such as ash and slag conveying as power plants ceramic slurry pump, coal slime conveying ceramic slurry pump, slurry conveying in metallurgical beneficiation plants ceramic slurry pump, coal slime ceramic slurry pump and heavy medium conveying ceramic slurry pump in coal washing plants, etc. The maximum weight concentration of solid-liquid mixture of ceramic slurry pump is 45% mortar and 60% slurry. The product has the advantages of high efficiency, stable operation, high reliability and long service life.

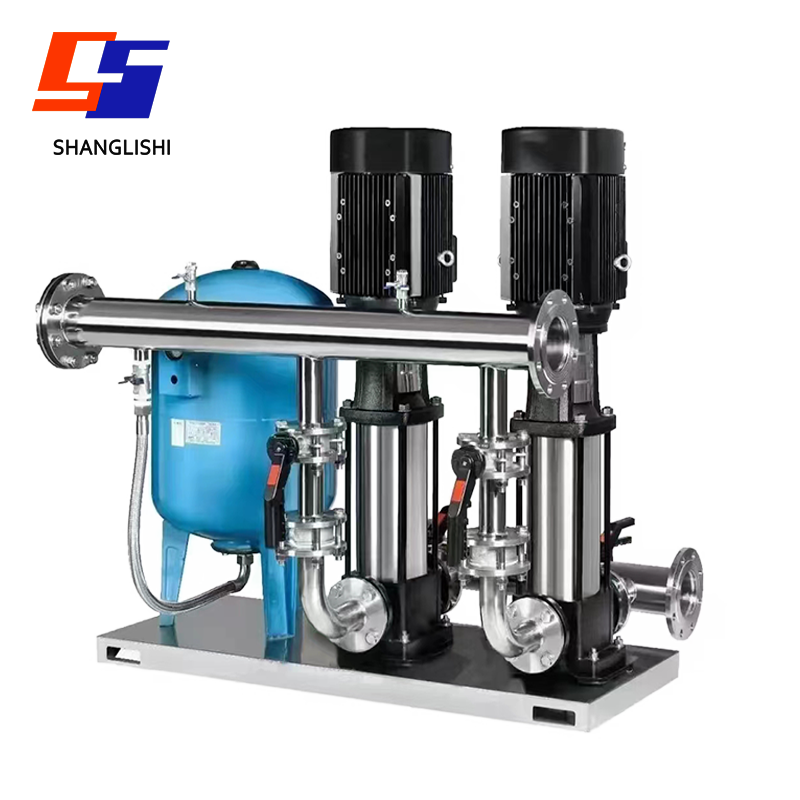

SDL, SDLR type vertical multistage centrifugal pump, has the advantages of compact structure, low noise, smooth operation, small footprint. This series of products adopts excellent hydraulic model, which has the characteristics of high operating efficiency, wide efficient area and light performance coverage, and can operate for a long time under efficient and economical working conditions. SDL type is an ordinary vertical multi-stage pump, which is used to transport liquid temperature ≤ 80 ℃, non-corrosive clean water or liquid with similar specific gravity. It is suitable for floor fire domestic water supply and cooling circulating water for air conditioning units.

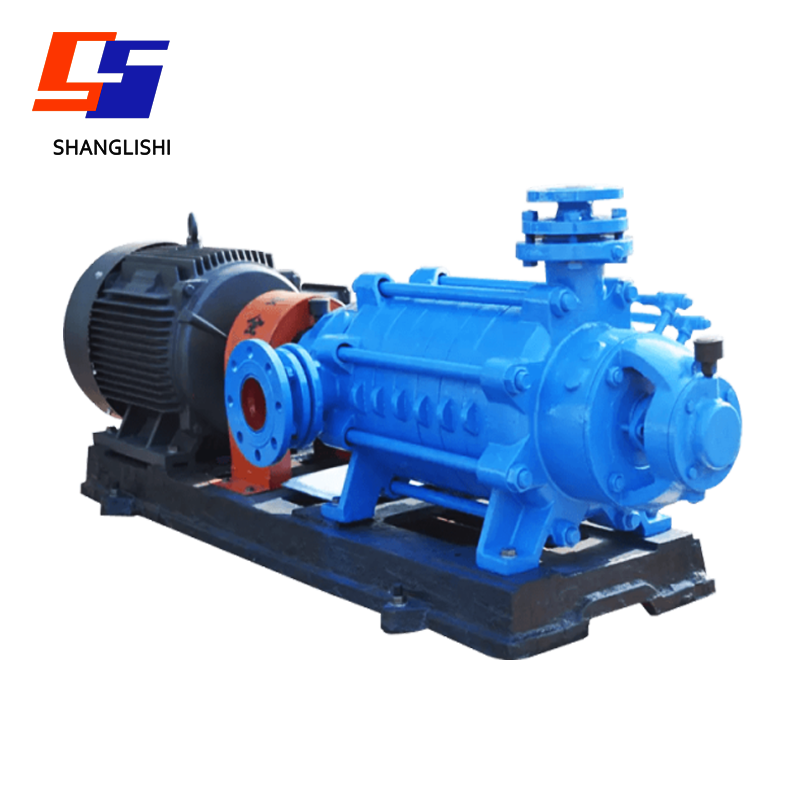

This series of horizontal multi-stage pumps adopt the high-efficiency and energy-saving hydraulic model recommend used by the country. It has the advantages of high efficiency and energy saving, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. By changing the material of the pump (or the material of the pump flow part), sealing form and increasing the cooling system, hot water, oil, corrosive and material-containing media can be transported.

SZX series self-priming pump is a self-priming centrifugal pump. It has the advantages of compact structure, convenient operation, convenient maintenance, high efficiency, long life, and strong self-priming ability. There is no need to install the bottom valve in the pipeline, and only need to keep the quantitative liquid in the pump body before work, thus simplifying the pipeline system and improving the working conditions.

Slurry pumps are widely used in many industries, so people may need the replacement of mines slurry pump accessories, thermal power plants slurry pump accessories, metal smelting slurry pump accessories, coal washing slurry pump accessories, environmental protection slurry pump accessories and other industries slurry pump accessories, used to transport some slurry containing abrasive solid particles.

The flow-through parts of Shangli stone slurry pump are equipped with high chromium alloy, ceramic, polyurethane, rubber and other corrosion-resistant and wear-resistant materials, which can meet the transportation engineering of high concentration and large particle slurry.

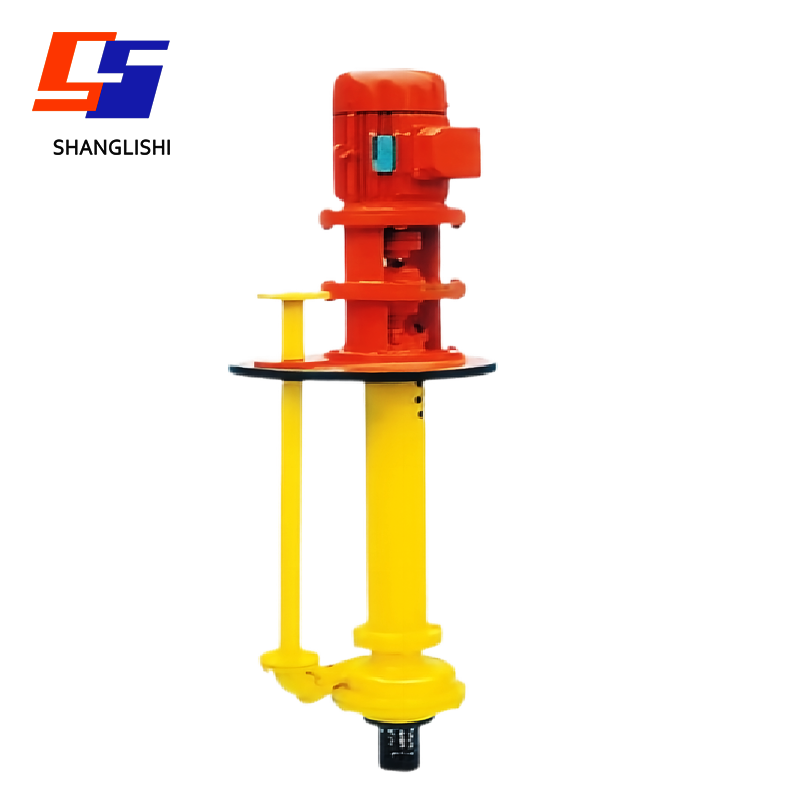

SFY series liquid pump is a vertical single-stage single-suction pump, used for conveying solid particles and not easy to crystallize the corrosive liquid. The temperature of the transported medium is -20 degrees Celsius -150 degrees Celsius. Special needs can be -50 ℃-150 ℃. The pump has the characteristics of small footprint, reliable use, convenient maintenance, and strong corrosion resistance. At the same time, it cancels the mechanical seal commonly used in other submerged pumps, and selects a unique structure of the impeller, so that the pump has no leakage and long life. It is widely used in petroleum, chemical, pharmaceutical, papermaking, metallurgy, sewage treatment and other industries.

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP