SH/SCZ/SZA Series Chemical Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Specification

Horizontal Chemical Centrifugal Pumps – SH/SCZ/SZA Series Chemical Pump: Advanced Chemical Transfer Pump Solutions

Shanglishi SH/SCZ/SZA Series Chemical Pump stands out as a premier solution for industrial chemical transfer pump applications, offering unmatched durability and efficiency right from the start. This comprehensive overview of SH/SCZ/SZA Series Chemical Pump demonstrates our commitment to highest standards, ensuring experience, expertise, authoritativeness, and trustworthiness throughout every section.

The SH/SCZ/SZA Series Chemical Pump is engineered for transferring corrosive, abrasive, and toxic fluids safely and efficiently. As a type of horizontal chemical centrifugal pumps, these devices are designed with robust construction using corrosion-resistant materials such as stainless steel (SS304/SS316), cast steel, and advanced fluoroplastic alloys. With a focus on industrial applications, this chemical transfer pump excels in demanding environments by offering high flow rates, moderate to high pressures, and reliable sealing mechanisms.

★ Chemical centrifugal pumps are single-stage, horizontal, radial partial case pumps. The Chemical centrifugal pump is suitable for conveying neutral or corrosive liquids, especially liquid petrochemicals of various temperatures, acid and alkali solutions of various temperatures and concentrations, and other corrosive liquids.

★ The Chemical centrifugal pump is ideal for use in petroleum refining, petrochemical refining, chemical industry engineering, electric power engineering, environmental protection engineering, oil transmission engineering, paper making, pharmaceuticals, sugar making, and other industries.

★ SH/SCZ/SZA series chemical centrifugal pumps are products independently developed by our company.

★ Patent number: ZL202122043784.4, ZL202122901739.8

★ SH/SCZ/SZA Series chemical centrifugal pumps are designed and produced in accordance with API610 specifications. The SZA chemical centrifugal pump body is supported by feet, featuring a single suction radial impeller, axial suction, and radial discharge.

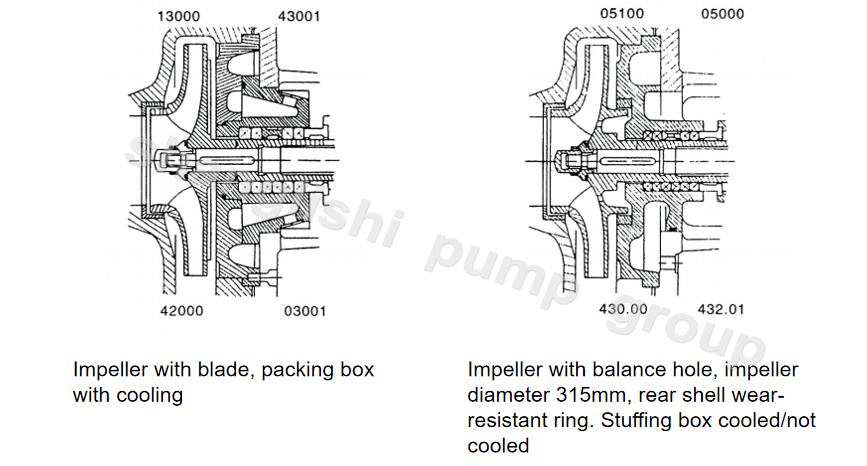

★ Depending on usage conditions, use front and rear mouth rings and balance holes for hydraulic balance. The stuffing box has cooling or heating pipe connections. The shaft seal of the chemical centrifugal pump is sealed with stuffing, and single-end or double-end mechanical seals can also be used. Additionally, the pump is equipped with a cooling, flushing, or sealing liquid system.

Working conditions

Chemical Centrifugal Pump Specifications:

Head: Up to 160m

Flow rate: Up to 2000 m³/h

Working pressure: 2.5 MPa

Working temperature: -80°C to 300°C

Key Features

Material Durability: Constructed from premium materials including PTFE and PFA linings, ensuring long-term resistance to acids, alkalis, and other reactive fluids.

Sealing Mechanisms: Options such as mechanical, labyrinth, and packed gland seals provide robust protection against leakage even under high-temperature conditions (up to 200°C).

Design Flexibility: Available in single-stage or multistage configurations, the SH/SCZ/SZA Series Chemical Pump adapts seamlessly to varied industrial needs while maintaining a compact, horizontal layout for space efficiency.

Performance Efficiency: With flow rates up to 2000 m³/h and head capacities reaching 160 meters, these pumps deliver exceptional hydraulic efficiency and energy savings.

Applicable Mediums for Chemical Centrifugal Pumps:

Acids: Suitable for handling various temperatures and concentrations of sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, and other inorganic or organic acids.

Alkaline solutions: Efficiently transports sodium hydroxide, sodium carbonate, and other alkaline concentrates at different temperatures and concentrations.

Coating industry processes: Ideal for use in degreasing, phosphating, electrophoresis, and other chemical processes within the coating industry.

Petrochemical and organic compounds: Can handle a variety of liquid petrochemicals, organic compounds, and other corrosive raw materials or products.

Our factory's corrosion-resistant materials ensure that the certified chemical centrifugal pumps meet the demanding requirements of these media. When placing an order, please provide detailed information about the medium to be transported to ensure optimal performance.

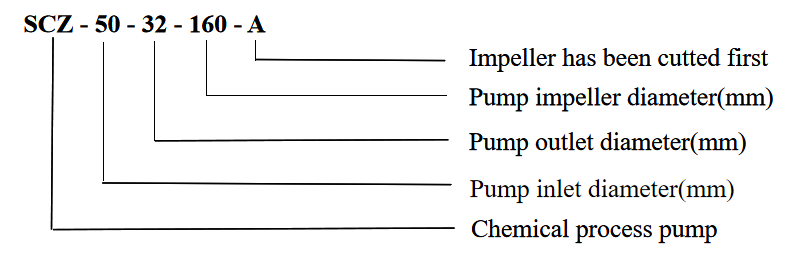

Model Meaning

Product Advantage

SH/SCZ/SZA Series Chemical Process Centrifugal Pump

The SH/SCZ/SZA series Chemical Centrifugal Pumps are designed according to standard API specifications. These pumps offer versatile solutions for various applications, capable of handling clean media, media containing particles, and even small amounts of gaseous content. Additionally, they excel in transporting media that are high-temperature, low-temperature, or highly corrosive.

Key Features:

Impeller Types:

Available in three variations – closed, semi-open, and open impellers. Each type is equipped with a balance hole and a corrosion-resistant ring, ensuring axial force balance during operation.Pump Body & Bearing Frame Connection:

The pump body is connected to the bearing frame via an intermediate section. For strong corrosive media, materials in this intermediate section can be customized to avoid excessive corrosion to the bearing frame.Cooling Systems:

A water-cooling cavity in the intermediate section circulates cooling water to prevent high-temperature media from transferring excessive heat to the bearing, thus ensuring the pump's longevity.Sealing Options:

Sealing Mechanisms:

Options include stuffing seals, single or double-end mechanical seals, and cartridge-type single-end mechanical seals. These seal types adhere to API682 design standards, ensuring reliability for diverse applications.Bearing Frame Designs:

Cooling Methods:

Three bearing frame designs are available: Bearings are lubricated with thin oil, and the oil is cooled by water circulating through the cooling chamber, keeping the bearings in optimal working condition.Air-cooled heat sink

Air-cooled fan

Water-cooled cavity

Advantages of SHANGLISHI Chemical Centrifugal Pumps:

Compliance with Standards:

All Chemical Centrifugal Pumps from SHANGLISHI meet strict safety and industry regulations, including API (American Petroleum Institute) and ANSI (American National Standards Institute).Leakage Prevention:

Equipped with advanced safety features, our Chemical Centrifugal Pumps ensure minimal risk of hazardous fluid leakage, providing enhanced operational safety for various industries.Comprehensive Technical Support:

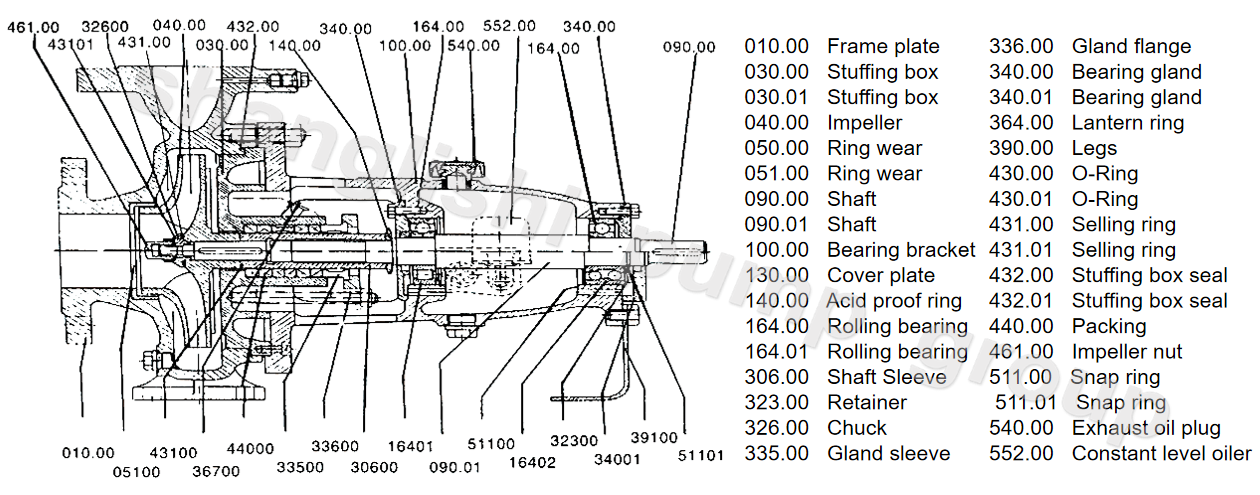

SHANGLISHI Group offers full technical support, including pump selection, installation assistance, and ongoing maintenance, ensuring that Chemical Centrifugal Pumps perform optimally and have a long service life.Product Structure

Product Features

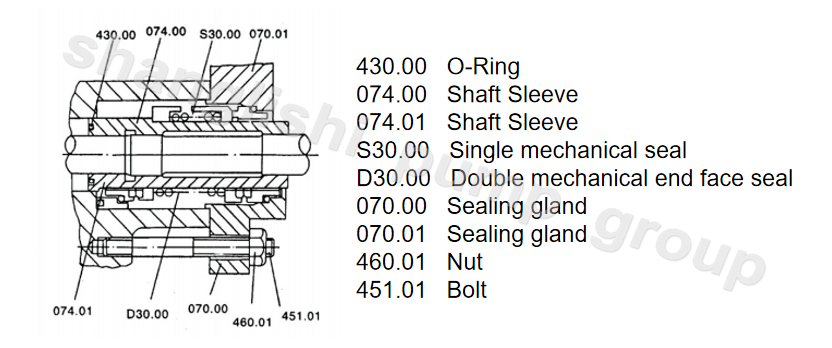

Balanced Pressure on Shaft Seal:

The pressure acting on the shaft seal is balanced by the balance hole on the impeller blade. The shaft seal can use a soft packing seal (with or without cooling) or a variety of single and double mechanical seals, depending on the needs of the operation.Durable Bearings and Abundant Shaft Diameter:

Chemical centrifugal pumps are equipped with durable ball bearings and a sufficiently large shaft diameter, ensuring smooth and reliable operation over time.Double Screw Housing Design (for Some Specifications):

To balance radial forces, certain pump models feature a double screw housing. The bearing frame, including components like the shaft, impeller, and stuffing box, is part of a combined unit. This allows for easy maintenance without the need to remove the pump body from the pipeline. If an extended coupling is used, even the motor does not need to be removed.Flange Design:

Flanges are available in two configurations, PN16 and PN25, depending on the material requirements, offering flexibility in installation and usage.Horizontal Rear Door Structure:

The pump head is connected to the motor by a coupling and mounted on a baseplate. The rear-open impeller design, combined with three bearings and an external mechanical seal (with a cooling device), ensures efficient performance. The bearing oil level is monitored via an oil mirror for easy observation.Pump Body with Foot Design:

The pump body includes a foot, which supports the load from the pipeline and transfers it directly to the foundation. This prevents the pump rotor from bending due to external load, which in turn extends the lifespan of both the bearings and the mechanical seal.Easy Maintenance:

Maintenance of Chemical Centrifugal Pumps is simple and convenient. The pump body does not need to be disconnected from the pipeline. By removing the bracket and bolts, the impeller and mechanical seal can be accessed and maintained effortlessly.In-line Inlet and Outlet:

The inlet and outlet of the pump are aligned on the same axis, making it convenient for integration into the design and simplifying the connection process.Partial view of mechanical seal

Advantages and Maintenance

Ease of Maintenance: The horizontal split-case design enables quick access to the impeller and seals, reducing downtime and maintenance costs.

Energy Efficiency: Optimized impeller designs enhance hydraulic performance, contributing to lower operational expenses.

Advanced Cooling Systems: Integrated cooling channels and water-cooling cavities help manage high-temperature media, ensuring longevity and reliability.

Robust Construction: With a sturdy pump body and innovative bearing frame connections, the SH/SCZ/SZA Series Chemical Pump offers exceptional resistance against external loads and corrosion.

The Shanglishi SH/SCZ/SZA Series Chemical Pump exemplifies high-performance horizontal chemical centrifugal pumps with proven reliability and adaptability in harsh chemical environments. This state-of-the-art chemical transfer pump is designed to meet the rigorous demands of industries ranging from petrochemical refining to water treatment and pharmaceuticals. With its innovative features, robust technical specifications, and superior ease of maintenance, our horizontal chemical centrifugal pumps remain the ideal choice for your industrial fluid handling needs. Trust in the SH/SCZ/SZA Series Chemical Pump to deliver outstanding performance every time, ensuring safety and efficiency from installation to operation.

Product Usage

It can transport inorganic acid and organic acid solutions such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations; alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations; various salt solutions; various liquid petrochemicals products, organic compounds, and other corrosive liquids. This type of pump is suitable for oil refinery, petrochemical industry coal processing engineering, low temperature engineering, paper industry, sugar industry, water supply plant, seawater desalination plant, power plant, environmental protection engineering and shipbuilding industry, etc. Viewed from the motor side, the pump rotates in a clockwise direction.

Applications

The pump is suitable as petroleum refining chemical pump, petrochemicals refining chemical pump, chemical industry engineering chemical pump, electric power engineering chemical pump, environmental protection engineering chemical pump, oil transmission engineering chemical pump and paper making chemical pump, pharmaceutical chemical pump, sugar making chemical pump and other industries chemical pump. Our SH/SCZ/SZA Series Chemical Pump is ideal for a wide range of industrial settings:

Chemical Processing Chemical Pump: Efficiently transferring acids such as sulfuric, nitric, hydrochloric, and phosphoric acids, making it a reliable choice for chemical transfer pump operations.

Water and Waste Management Chemical Pump: Perfect for handling clarified water, sewage, and sludge in treatment plants.

Oil and Gas Chemical Pump: Suitable for fuel transfer, refinery processes, and offshore applications.

Pharmaceuticals Chemical Pump & Food Industries Chemical Pump: Ensuring hygienic and safe handling of sensitive fluids.

Marine Chemical Pump and Industrial Sectors Chemical Pump: Adaptable for shipboard systems and industrial cooling circuits.

Particularly suitable for the chemical and petrochemical industries

Especially suitable for oil refineries

Especially suitable for paper mills, pulp industry and coating industry

Widely used in chemical, fertilizer, petroleum and other industries

Suitable for food, pharmaceutical and synthetic fiber industries

Suitable for metallurgy, electric power and other industries

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including:ChinaHuadian,ChinaDatang Group,Datang International, ChinaHuaneng, ChinaState Investment, ChinaGuodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel, Yanshan Iron and Steel, Jiujiang Wire, Jiujiang Pinggang, Donghai Special Steel, etc.

Application of Chemical Pump in Petrochemical Industry

Application of chemical pump in petroleum industry

Application of Chemical Pump in Synthetic Fiber Industry

Application of Chemical Pump in Electric Power Industry

Application of Chemical Pump in Electric Power and Metallurgical Industry

Application of chemical pump in food and pharmaceutical industry

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP