SLZG Series High-Efficiency Self-Priming Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product overview

SLZG High-Efficiency Energy-Saving Self-Priming Pumps

Shanglishi SLZG high-efficiency self-priming pumps are ideal for applications in industries such as steel, metallurgy, petroleum, chemical, electric power, environmental protection, municipal, and construction. Designed with advanced self-priming pump technology, these pumps ensure efficient, reliable performance across demanding environments.

· Widely Used Across Industries: Applicable in steel, chemical, and environmental protection sectors.

· Heavy-Duty Design: Handles high temperatures, pressures, and wear conditions, making it a perfect upgrade for traditional pumps like long-shaft and submersible pumps.

Advantages of SLZG Self-Priming Pumps

Temperature Resistance: Handles high temperatures without performance loss.

Pressure Resistance: Suitable for high-pressure applications.

Wear Resistance: Long-lasting with minimal wear over time.

Key Features of SLZG Self-Priming Pumps

Superior Self-Priming Performance

· Incorporates vacuum pump principles for reliable operation.

· Features an electric air control valve for "one-time drainage, lifelong self-priming.

Energy-Efficient Design

High-efficiency hydraulic model reduces power requirements by 1-3 levels compared to ordinary pumps.

· CFD-optimized flow components further enhance efficiency.

Innovative Sealing System

·No-leak sealing eliminates traditional issues like dripping and wear, prolonging service life.

Durable Materials

· Constructed with wear-resistant cast steel and cast iron.

· Anti-cavitation materials ensure longevity under tough conditions.

Flexible and Cost-Effective

· Modular design allows easy replacement of impellers and guide parts without altering the pump base.

· Reduces downtime and maintenance costs.

Advanced Features of SLZG Self-Priming Pumps

-

Gas-Liquid Separation Chamber: Ensures stable performance with minimal flow loss.

-

Automatic Control Valve: Prevents siphon effects and supports consistent operation.

-

Cavitation Resistance: Superior suction performance minimizes cavitation damage.

-

Smooth and Quiet Operation: Low vibration and noise levels for improved user experience.

Reliable, No-Leak Sealing Technology

Innovative Sealing System: Utilizes both power and auxiliary seals, eliminating traditional packing and mechanical seals.

No-Leak Operation: Prevents issues like "running, dripping, and leaking," common in traditional water pumps.

Long Lifespan: Sealless self-priming technology ensures no friction or wear, extending the pump's service life.

Superior Self-Priming Performance

Vacuum Pump Principle: Incorporates vacuum pump technology for reliable self-priming.

Electric Air Control Valve: Achieves "one-time drainage, lifelong self-priming" performance.

Enhanced Efficiency and Energy Saving

High-Efficiency Hydraulic Model: Optimized design for higher efficiency than regular self-priming pumps.

Energy-Saving: Supporting motor power is reduced by 1-3 levels compared to conventional pumps, resulting in significant energy savings.

Advanced Structural Design

Gas-Liquid Separation Chamber: Ensures self-priming without significant flow loss.

Soda-Water Separation Method: Provides stable self-priming performance without the need for vacuum pump assistance.

Automatic Control Valve: Prevents siphon effects, ensuring consistent performance over the pump's lifetime.

Computational Fluid Dynamics (CFD) Optimized

CFD Technology: Systematically designed for optimized flow components, improving overall efficiency.

Special Sealing Structure: Reduces sealing loss by 95%, further improving energy efficiency.

Easy Replacement and Cost Reduction

Modular Design: Impeller and guide parts are replaceable without changing the pump base, reducing both replacement time and cost.

Excellent Automatic Control and Cavitation Performance

Automatic Control: Fully compatible with high-tech systems and automated processes.

Cavitation Resistance: Better suction performance compared to standard self-priming pumps, reducing cavitation damage.

Wear-Resistant Materials and Durability

Durable Flow Parts: Made of wear-resistant materials, with impellers built from anti-cavitation materials for an extended lifespan.

Axial Force Elimination: Unique design eliminates axial force, prolonging the pump's service life.

Smooth and Flexible Operation

Low Vibration & Noise: Operates quietly with minimal vibration.

Easy Maintenance: Simple to disassemble and install, requiring no fixed anchor, making it highly flexible.

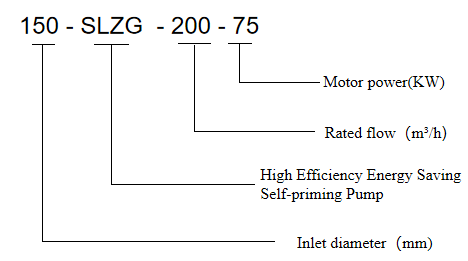

Model meaning

Working conditions

Working conditions

Speed: 2950r/min,1480r/min,980r/min

Suction discharge diameter: 50-500mm

Rated flow: 7.5-2500m ³

Rated lift: 10-125m

Suction height: 4-7m

Temperature range: ambient temperature is generally ≤ 45 ℃, maximum liquid temperature ≤ 80 ℃

Medium: clear water or liquid with physical and chemical properties similar to clear water

Product features: self-priming performance is reliable, the real realization of "a drainage, life-long self-priming"

Material: cast steel, cast iron

Why Choose SLZG Self-Priming Pumps?

· Reliable Performance: Ensures efficient self-priming in every application.

· Energy Savings: Reduces operating costs with lower motor power requirements.

· Durability: Built with wear-resistant materials for extended service life.

· Easy Maintenance: Modular design simplifies part replacement, reducing downtime.

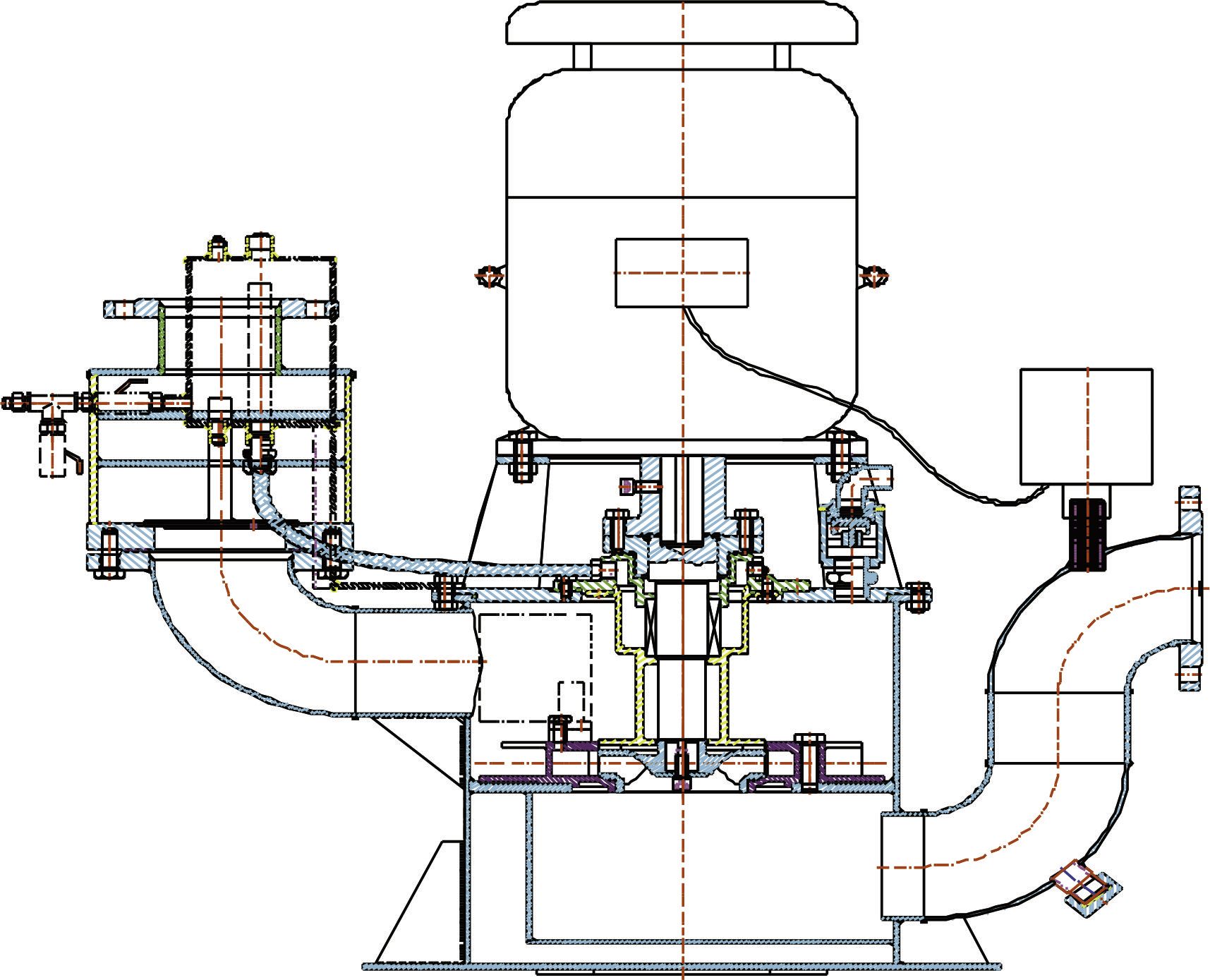

Product Structure

Structure and Working Principle of Self-Priming Pump

SLZG type non-sealed automatic self-priming pump is mainly composed of pump body, impeller, pump cover, guide vane, auxiliary impeller, pump shaft, connecting frame, electric air control valve and other parts. The pump body consists of a suction chamber, a liquid storage chamber and a gas-liquid separation chamber. After the pump starts normally, the impeller sucks the liquid stored in the suction chamber and the air in the suction pipeline together. The liquid mixed gas is discharged into the gas-liquid separation chamber through the guide vane under the centrifugal force of the high-speed rotation of the impeller.

Due to the sudden decrease of the flow rate, the specific gravity of the gas and the liquid is different, and the lighter gas is separated from the mixed liquid and excluded from the pump, the degassed liquid re-enters the working chamber and the air sucked in from the suction pipeline inside the impeller is mixed again. Under the rotation of the impeller, a certain degree of vacuum is quickly formed at the inlet of the pump body, so as to achieve the purpose of self-priming. Since the pump has a unique exhaust function, the pump can transfer liquid containing gas and does not need to install a bottom valve. The pump is equipped with an electric air control valve.

During operation, the control valve is closed to achieve sealing. After shutdown, the control valve is opened to destroy the vacuum in the suction pipeline and prevent the liquid in the pump chamber from flowing out of the suction pipeline due to siphon effect after shutdown. Ensuring that enough liquid is stored in the pump chamber to continue the next self-priming process, thus realizing the first drainage and permanent self-priming.

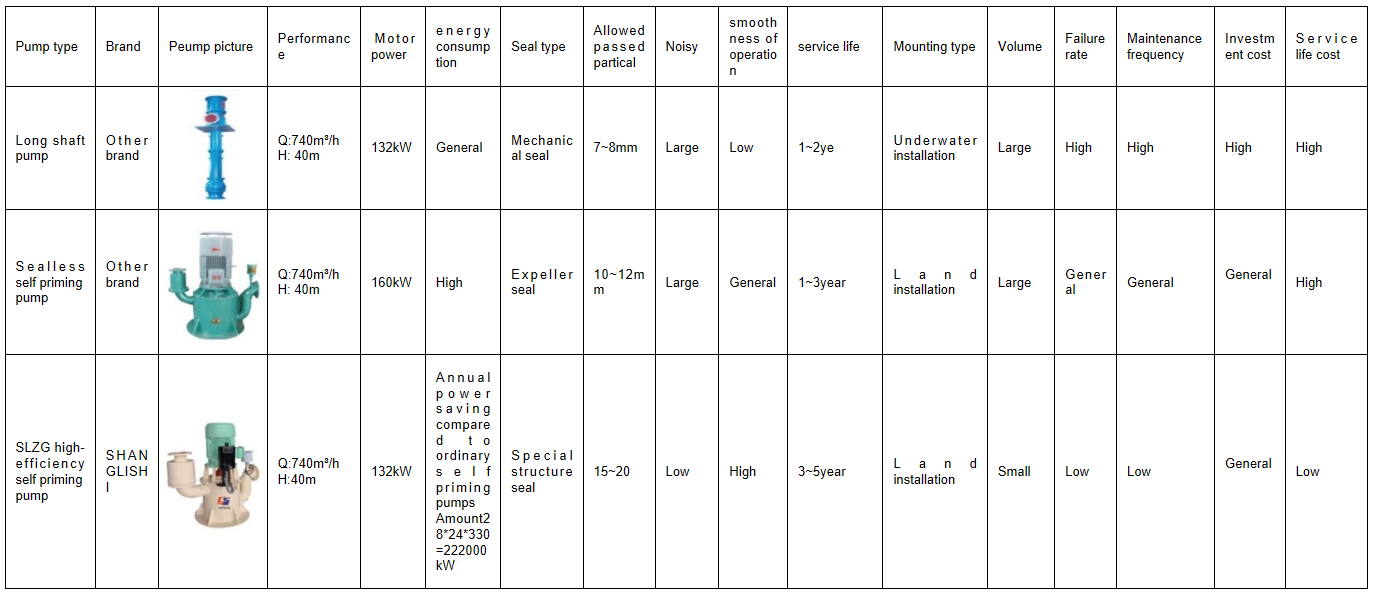

Energy saving comparison table of important parameters

Industry Applications

Industry Applications

steel industry self-priming pump, metallurgy industry self-priming pump

oil industry self-priming pump

electric power self-priming pump

environmental protection self-priming pump

municipal engineering self-priming pump

construction self-priming pump

-

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including: china Huadian, China Datang Group, Datang International, China Huaneng, China SDIC, China Guodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel Group, Yanshan Iron and Steel, etc.

Application of SLZG high efficiency and energy saving self priming pump in iron and steel, metallurgy, petroleum, chemical industry, electric power, environmental protection, municipal administration, construction and other industries

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP