SOM Series Double Suction Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Overview

Double Suction Submersible Motor Pumps: Industrial Double Suction Pumps for High-Flow Efficiency

Industrial Double Suction Pumps provided by Shanglishi are engineered to deliver unmatched performance in high-flow applications. Designed for rigorous use in municipal, industrial, and agricultural sectors, these pumps exemplify reliability and cutting-edge technology from a leading Pump Manufacturer & Supplier - Shanglishi.

Our certified Industrial Double Suction Pumps feature a centrifugal design with a double-sided impeller, allowing fluid to enter from both sides simultaneously. This innovative configuration minimizes axial thrust and optimizes hydraulic performance. Ideal for heavy-duty applications, the pumps are available in configurations such as the Single Stage Double Suction Centrifugal Pump and the Split Case Double Suction Pump, ensuring ease of maintenance and superior operational efficiency.

The Shanglishi SOM Series Double Suction Pump is a high-efficiency medium-opening single-stage double-suction centrifugal pump. This pump adopts a linear design and is equipped with reinforcing ribs to make its structure more reasonable. Its beautiful appearance and stable installation ensure a robust performance. The short bearing spacing improves the rigidity of the shaft, ensuring smooth operation, low vibration, and minimal noise. The fully sealed pump shaft design keeps it from contacting the conveying medium, ensuring the shaft remains rust-free, is easy to disassemble and assemble, and has a long service life.

Our double suction pump offers reliable performance, energy savings, convenient maintenance, and a long service life. Its design aligns with the GB/T5657 standard, making it a trusted solution in various industries.

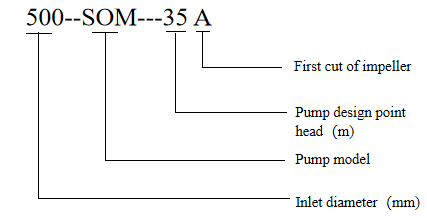

Model meaning

Structure Description

Key Features

Structural Design

Reinforced Ribs: Provide added strength and stability to the pump structure.

Short Bearing Spacing: Improves shaft rigidity for better performance and durability.

Sealed Pump Shaft: Prevents rusting and ensures long-lasting operation by keeping the shaft from contacting the conveyed medium.Maintenance and Assembly

The double suction pump features a simple design that allows for easy maintenance. The pump cover and upper cover of the bearing body are opened, enabling the entire rotor to be removed easily.

The shaft seal can be equipped with either a mechanical seal or a packing seal, depending on user requirements.Hydraulic and Structural Optimization

Molded Components

The Shanglishi Split Case Double Suction Pump body and pump cover are cast using resin sand, ensuring accurate shape, smooth surface, and improved hydraulic efficiency.

Hydraulic Performance

Our Industrial Double Suction Pumps uses an excellent hydraulic model and benefits from CFD optimization design to improve hydraulic efficiency and cavitation performance.

The finite element method (FEM) is employed for strength calculations, enhancing reliability and durability, and extending the double suction pump's service life.

Bearing Design

Some bearings are designed with water-cooled structures, making them suitable for high-temperature environments.

Corrosion Resistance

The shaft sleeve surface can undergo special treatment or use stainless steel, preventing rust and significantly extending the double suction pump's operational lifespan.Components and Assembly

Main Components

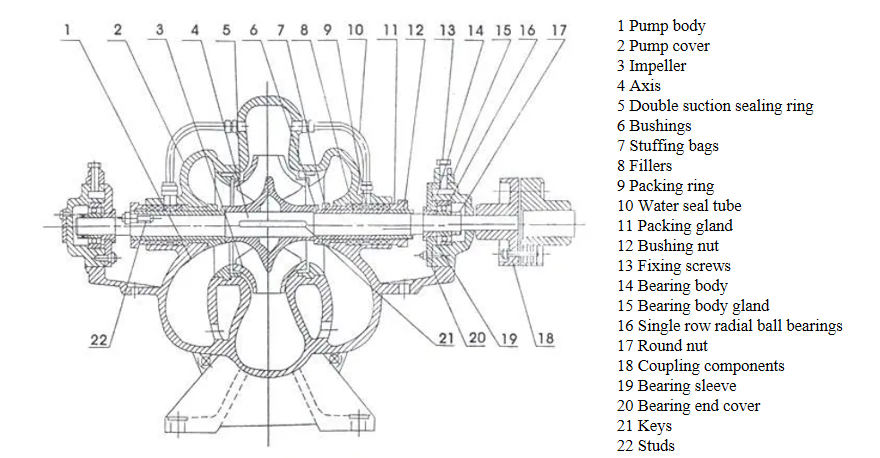

Shanglishi Single Stage Double Suction Centrifugal Pump is composed of several key parts: pump body, pump cover, shaft, impeller, seal ring, shaft sleeve, bearing parts, and packing seal (or mechanical seal).

The shaft is made from high-quality carbon steel, while most other components are made of cast iron. Impeller, seal ring, and shaft sleeve are considered vulnerable parts.

Working Chamber

Our Industrial Double Suction Pump body and cover form the working chamber for the impeller. The inlet and outlet flanges feature pipe screw holes for easy installation of vacuum and pressure gauges. There is also a threaded pipe hole at the lower part of the flanges for water discharge.

Impeller and Shaft Assembly

The impeller undergoes a static balance test before being fixed onto the shaft with a shaft sleeve and nuts on both sides. The axial position can be adjusted by the shaft sleeve nut. The symmetrical arrangement of blades and water on both sides of the impeller balances the axial force.

Bearings

Our Double Suction Submersible Motor Pumps uses radial ball bearings installed in the bearing body at both ends of the pump. These bearings are lubricated with butter, ensuring smooth operation.Sealing Mechanism

Double-Suction Sealing Ring

Shanglishi double suction pump uses a sealing ring to reduce water leakage from the pressure chamber back into the suction chamber, ensuring improved efficiency.

Shaft Seal

The shaft is sealed with a soft packing seal, which can also be replaced with a mechanical seal if required. To prevent air from entering the pump and cooling the lubrication seal cavity, a packing ring is installed between the packing. A small amount of high-pressure water flows into the packing cavity through a trapezoidal groove on the open surface of the pump cover to ensure a water seal.

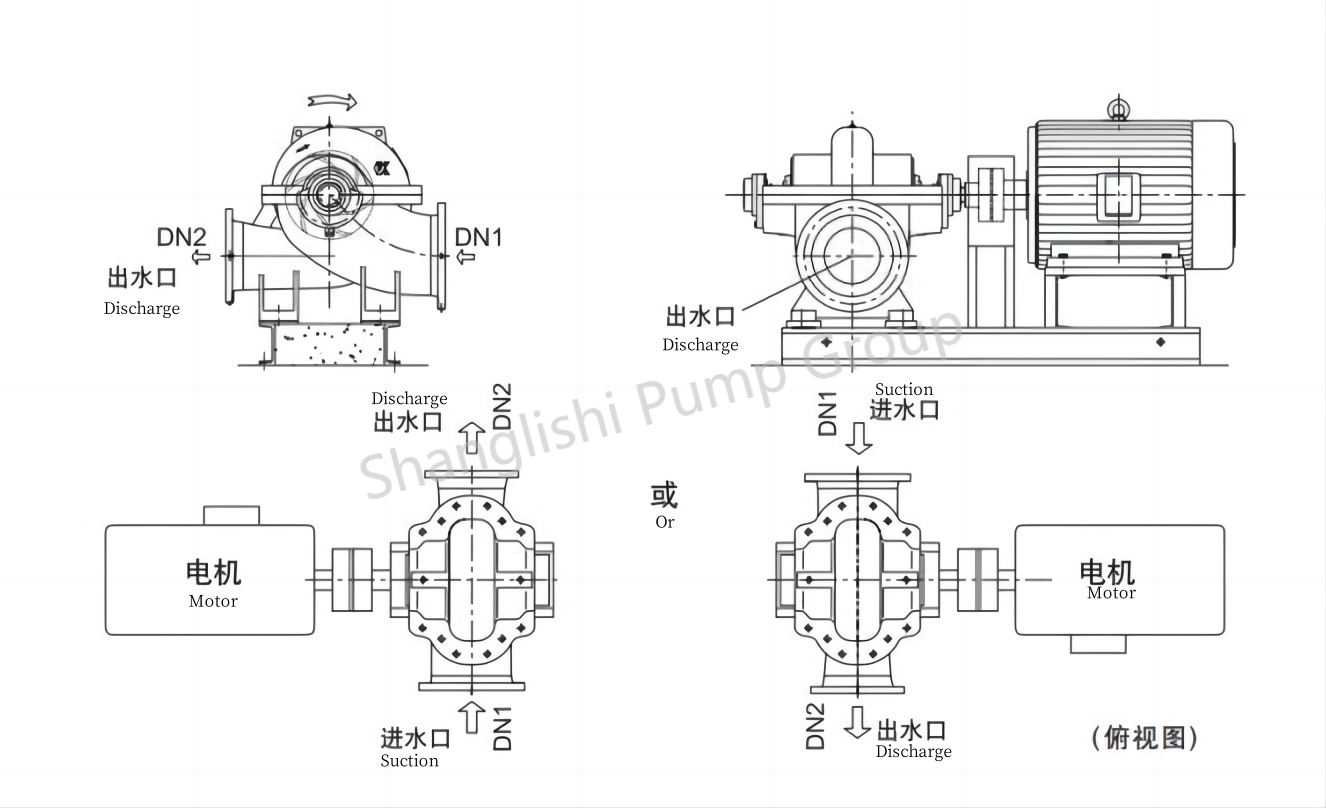

Drive MechanismThe SOM Series Double Suction Pump is typically driven directly by an electric motor through an elastic coupling. Alternatively, it can also be driven by an internal combustion engine when required.

Liquid Compatibility

The SOM Double Suction Pump is primarily used to pump clear water or clear water without solid particles, or other media with physical and chemical properties similar to water. By changing the material and sealing structure of the overflow parts, the pump can also handle other liquids. Please contact our company in advance if you intend to use the pump for other types of liquids.

Double Suction Pump Advantages

Suitable for High Load Conditions: Double-suction centrifugal pumps are well-suited for high-load, high-flow, and high-pressure applications. They are widely used in industrial and water treatment sectors.

High Adaptability: These pumps are versatile and can be used across various industries, such as water utilities, power generation, chemical processing, and construction, particularly in applications requiring high head and large volume fluid handling.

Enhanced Structural Stability: The symmetric design of the double-suction pump enhances the structural stability by preventing deformation due to unbalanced forces. This feature is particularly valuable in continuous operation systems.

High Head Capability: Double-suction centrifugal pumps are capable of achieving high head, making them ideal for applications that require long-distance fluid transport, such as water supply systems and cooling systems.Click here to view all of Shanglishi advanced and excellent pumps!

Product Structure Diagram

Installation method

Working Conditions

-

This double suction pump is widely used in urban water supply and drainage, urban water supply, central heating system water supply and drainage, iron and steel metallurgical enterprises, petrochemical refineries, paper mills, oil fields, thermal power plants, airport construction, chemical fiber plants, textile plants, sugar plants, chemical plants, power station water supply; factory, mine fire system water supply, air conditioning system water supply; farmland drainage irrigation and various water conservancy projects.

-

Municipal water supply and drainage: The pumps are often used in urban water supply systems and drainage facilities, and can effectively meet the needs of large flows.

Agricultural irrigation: In farmland irrigation, double suction pumps are used for pumping and irrigation to ensure that crops get enough water.

Industrial water: Many industrial processes require a lot of water, and they play an important role in industrial water systems.

Power plant cooling water system: In power plants, they are used to circulate cooling water to ensure the normal operation of equipment.

Water conservancy projects: In various water conservancy projects, such as dams and reservoirs, the pumps are used to transport and manage water resources.

Mine drainage: Double suction pumps are also widely used in mine drainage systems to help control water levels and ensure safe operations -

This product mainly conveys clear water or clear water without solid particles or other media with physical and chemical properties similar to water. By changing the material, sealing structure and method of the over-flow parts, other liquids can also be conveyed. Please contact our company in advance at that time.

Flow range 74-23500m³/h Head range 7-306m Speed 720,990,1480 and 2990r/min Power 15KW-2500KW Temperature range Maximum liquid temperature ≤ 80 ℃(~ 120 ℃) ambient temperature is generally ≤ 45 ℃ Medium Clear water or a liquid with physical and chemical properties similar to clear water Material Cast iron, stainless steel SS304,SS316,SS316L, etc SOM series energy efficient double suction pump with intelligent vacuum system:SOM series high-efficiency and energy-saving double suction pump is equipped with intelligent vacuum system, which is used when the pump is installed on suction. The intelligent vacuum system can make the pump's inlet pipeline system always in a full water state, automatically start when there is no water, and automatically shut down when the water is full. Can achieve automatic control, no personnel on duty. There is no need for water diversion measures such as irrigation or vacuuming before each start, no bottom valve, and high intelligence.

This pump product quality credit guarantee standard (AAA level), not only improve the efficiency, but also extend the service life of the unit, improve the overall operation reliability and safety of the equipment, and greatly reduce the life cycle cost.

Why Choose Shanglishi as Your Double Suction Pumps Supplier?

The advantages of our Industrial Double Suction Pumps include:

-

Extended Lifespan: Reduced axial thrust and vibration lead to less wear on bearings and seals.

-

Lower Maintenance: The split-case design simplifies inspections and repairs, reducing downtime.

-

Energy Savings: High operational efficiency results in lower power costs.

-

Versatility: Suitable for transporting various fluids—water, chemicals, slurries—with ease.

-

Quiet Operation: The balanced design minimizes noise and vibration for a smoother operation.

Customization Process

Our approach to customizing Industrial Double Suction Pumps includes:

-

Requirement Analysis: Assessing flow rate, head, fluid properties, and environmental conditions.

-

Material Selection: Choosing corrosion-resistant materials such as stainless steel for harsh chemical environments.

-

Configuration: Offering both horizontal and vertical mounting options based on space and application needs.

-

Sealing Mechanism: Selecting between mechanical seals for high-pressure or packing for cost-effective solutions.

-

Drive Type & Connection Standards: Integrating electric motors, diesel engines, or turbines with customizable flange ratings (ANSI, DIN) and impeller trimming for precise performance curves.

Shanglishi Industrial Double Suction Pumps represent the pinnacle of modern pump design, merging robust construction with high efficiency and low maintenance. Whether deployed as a Single Stage Double Suction Centrifugal Pump, a Split Case Double Suction Pump, or incorporated within a broader system, these pumps deliver reliable performance for critical applications. As an industry leader, we continue to set the standard for excellence in pump technology—ensuring that our Industrial Double Suction Pumps remain the preferred choice for demanding, high-flow operations, backed by our unwavering commitment to quality and innovation in every Industrial Double Suction Pumps installation.

Industry Applications

This product is widely used as urban water supply double suction pump and water drainage double suction pump, urban water supply double suction pump, central heating system water supply and drainage double suction pump, iron and steel metallurgical enterprises double suction pump, petrochemical refineries double suction pump, paper mills double suction pump, oil fields double suction pump, thermal power plants double suction pump, airport construction double suction pump, chemical fiber plants double suction pump, textile plants double suction pump, sugar plants double suction pump, chemical plants double suction pump, power station water supply double suction pump; factory double suction pump, mine fire system water supply double suction pump, air conditioning system water supply double suction pump; farmland drainage irrigation double suction pump and various water conservancy projects double suction pump.

Municipal Water Systems Double Suction Pump: Water supply, distribution, and wastewater treatment.

Power Plants Double Suction Pump: Cooling water circulation and boiler feed operations.

HVAC Systems Double Suction Pump: Large-building heating/cooling loops.

Agricultural Irrigation Double Suction Pump: High-volume water transfer for irrigation and drainage projects.

Industrial Processes Double Suction Pump: Chemical processing, oil refineries, and marine ballast systems.

Flood Control Double Suction Pump: Efficient dewatering and stormwater management during flood events.

Urban water supply and drainage, urban water supply

Water Supply and Drainage of Central Heating System

Iron and steel metallurgical enterprises, petrochemical refineries and other water supply and drainage

Water supply and drainage of thermal power plants, chemical plants, etc.

Water supply for fire fighting system and air conditioning system in factories and mines

Farmland drainage irrigation and various water conservancy projects

-

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including: china Huadian, China Datang Group, Datang International, China Huaneng, China SDIC, China Guodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel Group, Yanshan Iron and Steel, etc.

Double suction pump in fire system water supply case

Application of Double Suction Pump in Iron and Steel Metallurgical Industry

Practical Application of Double Suction Pump in Chemical Plant

Practical Application of Double Suction Pump in Petroleum Refining Plant Industry

Application of Double Suction Pump in Water Supply and Drainage of Power Station

Application of double suction pump in urban water supply and drainage and urban water supply

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP