SSW/SSWH Series Pipeline Pumps

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product overview

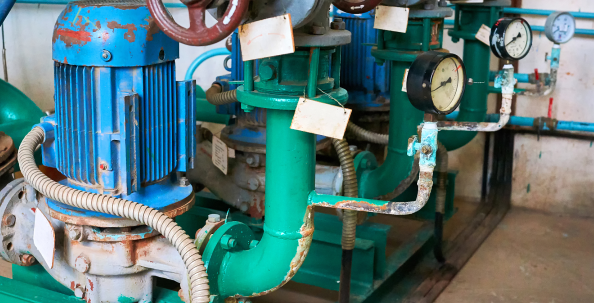

Shanglishi Single-Stage, Single-Suction Pipeline Pump:The SSW/SSWH series high-efficiency pipeline pumps feature single-stage, single-suction centrifugal design. These pumps offer energy savings, low noise, and stable performance, making them ideal replacements for traditional IS pumps. They excel in industrial water supply, HVAC cycles, and high-temperature boiler applications, and are customizable for corrosion-resistant and oil-based fluids.

SSG and SSW Vertical & Horizontal Direct-Connected Pipeline Pumps:

These pipeline pumps are designed for transporting clear water and other liquids with similar physical and chemical properties. They are suitable for industrial and urban water supply and drainage, high-rise building pressurization, garden irrigation, fire-fighting pressurization, long-distance transportation, HVAC systems, bathroom water circulation, and equipment matching. The service temperature for these pumps is T<80°C.SSRG (SSGRG) and SSRW Hot Water Circulating Pumps:

The SSRG and SSGRG pipeline pumps are widely used in industries such as energy, metallurgy, chemical, textile, and paper production. They are specifically designed for high-temperature hot water circulation in boilers for hotels, restaurants, and urban heating systems. The SSRG type operates at temperatures up to 120°C, while the SSGRG type can handle temperatures as high as 240°C.SSGH, SSWH Vertical & Horizontal Direct-Connected Chemical Pumps:

These pipeline pumps are designed for transporting liquids with solid particles, corrosive substances, and fluids with viscosities similar to water. They are ideal for industries like petroleum, chemical, metallurgy, electric power, paper, food, pharmaceuticals, and synthetic fibers, with operating temperatures ranging from -20°C to 120°C.SSYG, SSYW Vertical & Horizontal Direct-Connected Oil Pumps:

This series of pipeline pumps is designed for transporting petroleum products such as gasoline, kerosene, and diesel. These pumps are suitable for temperatures ranging from -20°C to 120°C, ensuring efficient and safe transport of oil-based mediums.Working conditions

Flow Range: 1-480m³/h

Head Range: 5-155m

Inlet Diameter: 50-200mmThe pipeline pump is designed for transporting clear water or other liquids with physical and chemical properties similar to clear water. If the medium contains fine particles, it is important to specify this during ordering to ensure the pump is equipped with a wear-resistant mechanical seal.

Material Options:

Gray Iron、Ductile Iron、SS304、SS316L

The maximum working pressure of the pipeline pump system is 1.6MPa. This means the combined pressure from the pump head and suction inlet should not exceed 1.6MPa. For systems requiring greater pressure, please specify this when ordering, so that the flow components and connection parts of the pump can be manufactured using cast steel materials.

The pipeline pump operates in environments where the ambient temperature does not exceed 40°C and the relative humidity stays below 95%.

Performance comparison between SSW series pipeline pump and traditional IS type pump:

Feature

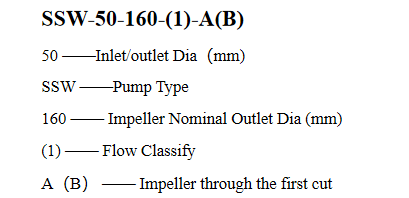

SSW Series pipeline pump Traditional IS-Type Pumps Efficiency High, energy savings of approximately 15%-20% Moderate Noise Low-noise design Higher vibration and noise levels Applicable Temperature Range -20°C to 240°C 0°C to 100°C Installation & Maintenance Easy to install and maintain Complex installation, frequent maintenance Material Options Flexible options: SS304, SS316L available Usually limited to single material Model meaning

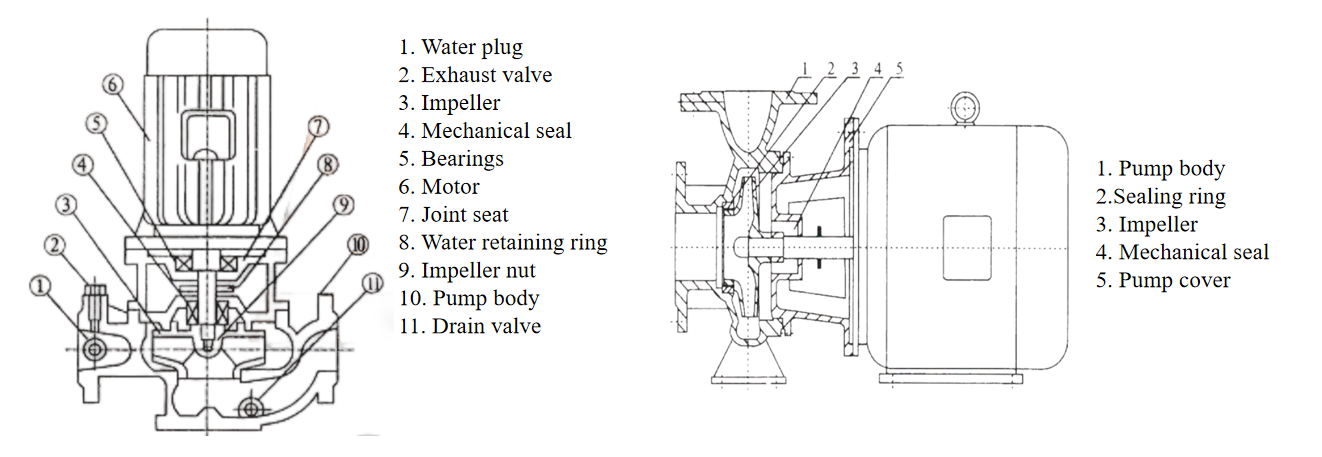

Product Structure

Product Structure

Our Pipeline Pump is engineered as a high-performance single centrifugal pump that efficiently transports fluids through extensive pipeline systems. Designed with advanced hydraulic modeling, the pump integrates a Y series motor directly connected to the water pump, a coaxial pump shaft enhanced by chrome plating for extended life, and a water retaining ring that protects the motor from leakage. The ingenious conjoined seat lowers the center of gravity, ensuring stability and reducing the cantilever effect of the shaft.

Innovative Features and Components

Key components of Shanglishi Industrial Pipeline Pump include:

Pump Shaft and Bearings: The shaft, aligned with the motor, minimizes noise and vibration, while high-quality bearings guarantee the accuracy and reliability of the mechanical seals.

Mechanical Seal: Crafted from stainless steel, tungsten carbide, and fluorine rubber, this seal withstands high temperature and pressure, ensuring no leakage or wear.

Pressure and Exhaust Valves: Integrated pressure plugs and vacuum gauges monitor pump performance, while the exhaust valve effectively drains trapped air.

Impeller: Featuring an efficient hydraulic model design, the impeller maximizes flow performance.

Additionally, our product line includes customized pipeline pumps that cater to unique industrial requirements, ensuring each system is tailored to achieve optimal performance.

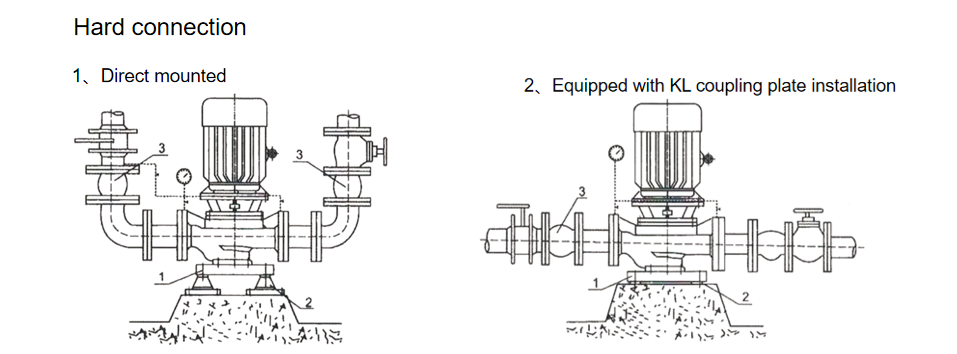

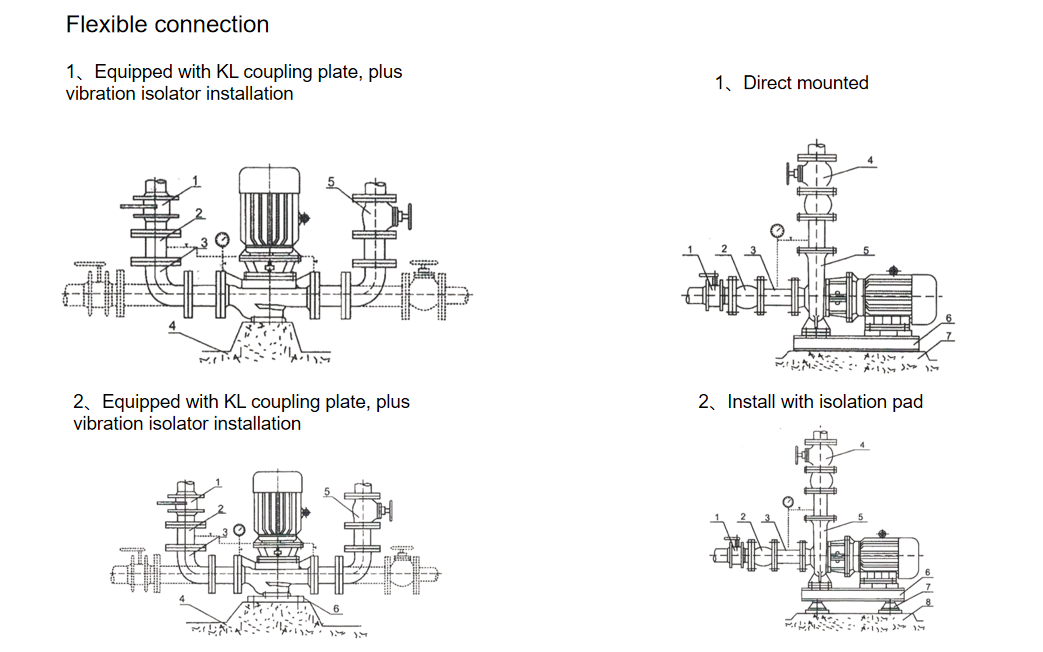

Pump appearance and installation drawing

Why Choose Shanglishi as Your Industrial Pipeline Pumps Supplier?

The Shanglishi Pipeline Pump offers significant benefits:

High Efficiency and Performance: The aerodynamic impeller design and optimized pump casing ensure minimal energy loss and consistent fluid flow, even under high-pressure conditions.

Durability and Robust Construction: Using corrosion-resistant materials such as stainless steel and high-grade alloys, our pump delivers long-term reliability in harsh environments.

Reduced Maintenance and Noise: The pump's design minimizes vibration and noise while extending service life, translating to lower maintenance costs.

Energy Efficiency: Its advanced hydraulic design reduces energy consumption, contributing to sustainable and cost-effective operation.

Choosing Shanglishi Pipeline Pump means investing in proven reliability and cutting-edge technology. With a robust design, customized configurations, and comprehensive support services, our pumps are trusted by industries worldwide. Whether installed as a single centrifugal pump or part of a larger fluid transport network, our Pipeline Pump consistently delivers performance and efficiency.

Our Pipeline Pump stands as a testament to advanced engineering, offering superior performance, durability, and energy efficiency across multiple applications. From municipal water systems to industrial fluid transport, the Pipeline Pump ensures a reliable, sustainable solution—making it the optimal choice for your fluid transport needs.

Applications:

The versatile Pipeline Pump is utilized across a range of industries:

Municipal and Industrial Water Supply: It ensures efficient water delivery and wastewater treatment with a consistent flow.

Oil and Gas: In the oil and gas sector, the pump is essential for transporting crude oil, refined products, and natural gas liquids safely.

Chemical and Petrochemical Processing: The pump handles hazardous chemicals, acids, and solvents with ease.

Mining, Construction, and Agriculture: It transports abrasive slurries, dewaters construction sites, and supports irrigation systems.

Single Centrifugal Pump Applications: Our solution is ideal as a single centrifugal pump that delivers high efficiency and reliability in various settings.

Vertical pipelines and horizontal direct-connected centrifugal pumps are suitable for urban water supply and drainage, high-pressure building pressurized water supply, fire pressurization, garden sprinkler irrigation, etc.

Vertical pipelines and horizontal direct-connected centrifugal pumps are suitable for long-distance transportation, HVAC and refrigeration cycles, bathroom and other cold and warm water circulation pressurization and equipment matching, etc. The operating temperature is less than 80 ℃.

Vertical pipeline, horizontal direct hot water (high temperature) circulating pump is suitable for energy, metallurgy, chemical textile, paper and other industries to use

Vertical pipeline and horizontal direct connection hot water (high temperature) circulating pump are suitable for boiler high temperature hot water pressurized circulating transportation and urban heating system circulation, and the hot water use temperature T<120 ℃

Vertical pipelines and horizontal direct-connected chemical pumps are suitable for petroleum, chemical, metallurgy, electric power, papermaking, food, pharmaceutical and synthetic fibers, etc., and the operating temperature is -20 ℃ ~ 120 ℃

Vertical pipelines and horizontal direct-connected oil pumps are suitable for transporting gasoline, kerosene, diesel and other petroleum products, and the operating temperature is 20 ℃ ~ 120 ℃

-

Enhancing Urban Water Supply Efficiency with Shanglishi Pipeline Pumps

Case Background:In 2021, a large Canadian city faced a sharp increase in water supply demand due to population growth and climate change. The municipal government urgently needed to upgrade its aging water supply system to ensure efficiency and reliability. To address this challenge, the government introduced customized pipeline pumps from Shanglishi Pump Group, leveraging their superior performance and adaptability for urban applications.

Project Implementation:

To meet the specific needs of the city, Shanglishi provided single centrifugal pumps with a flow rate of 340 m³/h and a head of 25 meters. The installation process was completed in just 4 hours, ensuring minimal disruption to the city's water supply.Performance Data Comparison:

Performance Indicators Shanglishi Pipeline Pumps Competitive Brand Pumps Flow rate (m³/h) 340 300 Head (m) 25 22 Installation time (hours) 4 8 Energy consumption (kW) 44 51 Noise level (dB) 65 75 Failure rate 1% 3%

The data highlights the clear advantages of Shanglishi’s Pipeline Pumps in critical performance metrics such as flow rate, head, energy consumption, and noise level.Actual Results:

After one month of continuous operation, the Shanglishi pipeline pumps successfully handled the city's peak water supply demands. The improved water supply efficiency and reduced failure rates led the municipal government to express high satisfaction with the results. Future plans include continued use of Shanglishi’s customized pipeline pumps for further system upgrades.Data Analysis and Discussion:

1. Superior Flow and Head Performance

The ability to deliver a higher flow rate and head ensures sufficient water supply during peak hours, meeting the demands of urban expansion. Shanglishi single centrifugal pumps effectively demonstrated their capacity to handle increased workloads in urban water systems.2. Fast Installation Efficiency

Quick installation, achieved within 4 hours, minimized disruptions to water supply. This efficiency is crucial in emergency upgrades and routine maintenance, making Shanglishi Pipeline Pumps a reliable choice for urban infrastructure.3. Energy Efficiency and Cost Savings

With a 25% reduction in energy consumption compared to traditional pumps, Shanglishi’s solutions significantly lowered operating costs. This not only benefited the municipal budget but also contributed to reduced carbon emissions.4. Noise Reduction for Improved Living Standards

Operating at only 65 dB, Shanglishi Pipeline Pumps ensured quieter operations, reducing noise pollution and improving the quality of life for residents in densely populated urban areas.5. Reliability and Safety

A failure rate of less than 1% underscores the reliability of Shanglishi’s pumps. This ensures consistent operation, reducing the risks of water supply interruptions and enhancing the overall safety of urban water systems.Conclusion:

Shanglishi Pump Group’s customized pipeline pumps have proven to be a transformative solution for urban water supply systems. Their superior flow capacity, energy efficiency, low noise levels, and high reliability make them an ideal choice for addressing the challenges of urbanization and climate change.As cities continue to grow and face increasing water supply demands, Shanglishi’s single centrifugal pumps and Pipeline Pumps are poised to play a crucial role in building resilient and efficient water systems.

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including:ChinaHuadian,ChinaDatang Group, Datang International,ChinaHuaneng,ChinaState Investment,ChinaGuodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel, Yanshan Iron and Steel, Jiujiang Wire, Jiujiang Pinggang, Donghai Special Steel, etc.

The use of pipeline pump in fire pressurization

The use of pipeline pump in urban heating system circulation

The use of pipeline pump in long-distance transportation

The use of pipeline pumps in chemical and other industries

The use of pipeline pumps in petroleum and other industries

The use of pipeline pumps in the energy industry

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP