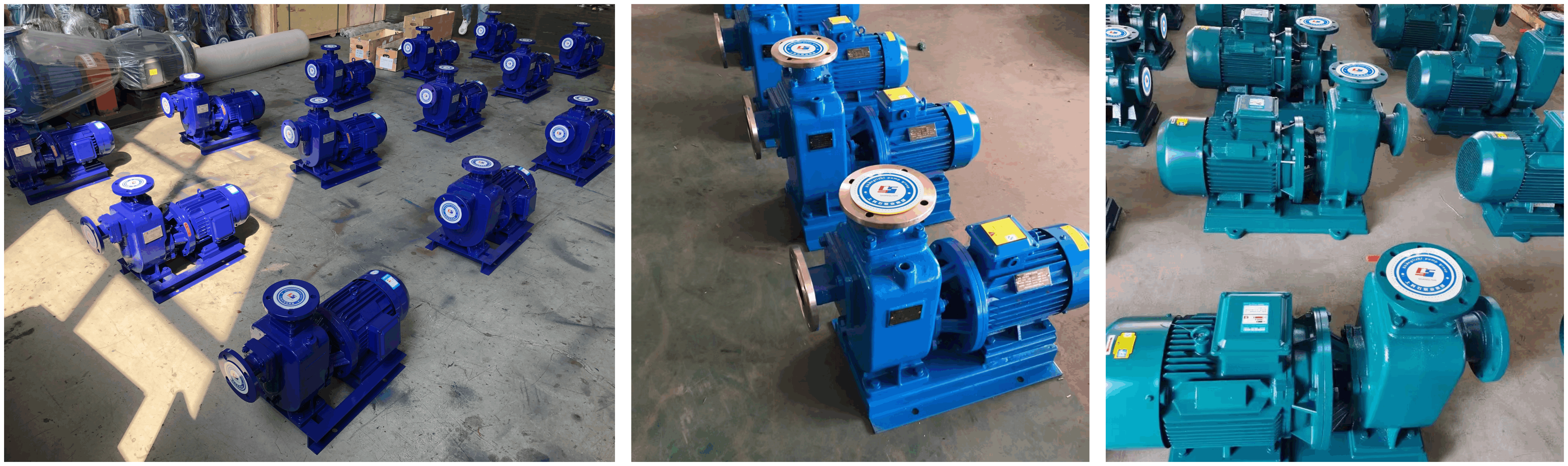

SZX Horizontal Self-priming Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Introduction

Product IntroductionLooking for an efficient and reliable self priming centrifugal pump? The Shanglishi horizontal self-priming centrifugal pump delivers outstanding performance for a wide range of industrial and sanitary fluid transfer applications. Our high-efficiency self-priming pump is designed to maintain optimal efficiency under challenging conditions, ensuring seamless operations and reduced maintenance efforts.

A self priming centrifugal pump is a unique type of liquid pump engineered to retain the necessary liquid inside the pump's cavity or body for starting the pumping process. Unlike standard centrifugal pumps, self-priming pumps eliminate the need for manual priming, significantly improving efficiency and reducing labor-intensive tasks.

1. Self-Priming centrifugal pump is suitable for urban environmental protection, construction, fire protection, chemical industry, pharmacy, dye, printing and dyeing, brewing, electric power, electroplating, papermaking, petroleum, mining, equipment cooling, tanker unloading, etc.

2. It is suitable for clear water, sea water, chemical medium liquid with acid and alkalinity, and slurry with general paste (medium viscosity ≤ 100 centipedes, solid content up to 30% or less).

3. The rocker-type nozzle is installed, and the water can be washed into the air and scattered into small raindrops for spraying. It is a good machine for farms, nurseries, orchards and tea gardens.

4. Self-Priming centrifugal pump can be used with any type and specification of filter press to send the slurry to the filter for pressure filtration.Features of Shanglishi High-Efficiency Self-Priming Pump

No External Equipment Required: The self-priming centrifugal pump operates without a foot valve, priming water, or other external devices. It automatically primes itself at startup, simplifying installation and maintenance.

Strong Self-Priming Capability: The pump can automatically draw liquid from the source, even in low or deep well conditions. Its strong self-priming ability makes it ideal for scenarios where the liquid source is below the pump or in challenging environments.

Versatility in Liquids: It can efficiently handle a wide range of liquids, including clean water, wastewater, liquids with gases, and both low and high-viscosity liquids. It excels in handling liquids with bubbles, foam, or minor impurities.

Reduced Maintenance Costs: The absence of foot valves, priming systems, and other auxiliary equipment significantly reduces installation and maintenance costs while streamlining operational processes.

Reliable and Durable: Made from high-quality corrosion-resistant and wear-resistant materials, the self-priming centrifugal pump is built for long-lasting, reliable operation, even under harsh conditions.

Quick Air Evacuation: The pump quickly expels air from the pump chamber at startup, restoring the self-priming function rapidly. This reduces startup time and enhances operational efficiency.Self-Priming Centrifugal Pump Applications

Self-priming centrifugal pumps are widely used in fluid transfer, drainage, and sewage applications. They are especially suited for the following scenarios:

Water and Wastewater Treatment: Self-priming centrifugal pumps are ideal for pumping wastewater, recycled water, and clean water, especially in low-water-source environments such as ponds or rivers. They provide efficient, reliable transfer from lower water levels.

Agricultural Irrigation and Drainage: The pump is capable of quickly drawing water from underground or reservoirs for irrigation, making it perfect for agricultural fields and large-scale irrigation systems.

Construction Site Water Supply and Drainage: These pumps are well-suited for large buildings, high-rise construction, and underground projects, where substantial water supply and drainage are needed. They can efficiently pump water from low levels to meet the daily demands of construction sites.

Chemical and Petrochemical Industries: The self-priming pump is capable of transferring corrosive liquids, foamy liquids, and liquids with minor impurities. It is widely used in industries like chemicals, petrochemicals, and pharmaceuticals, where acids, alkalis, oils, solvents, and other substances need to be pumped.

Firefighting Systems: In firefighting pump systems, the self-priming centrifugal pump can be used to efficiently extract water, ensuring a stable supply for emergency response and fire suppression.

Industrial Liquid Transfer: In chemical processing, pharmaceuticals, and food manufacturing, the self-priming centrifugal pump is ideal for transferring chemical solutions, slurries, and other liquids.If you need further details or specific technical information, feel free to contact Shanglishi!

Technical Specifications and Models

Technical Specifications and ModelsThe Shanglishi series of self priming centrifugal pumps features models designed to meet varied operational needs:

-

Model 50SZX12.5-60: Featuring a 50 mm suction port, a flow rate of 12.5 m³/h, and a lift capacity of 60 meters, this pump is perfect for both clean water and slurry transfer applications.

-

Options available include standard installations as well as mobility-enhanced configurations like the selfpriming centrifugal pump on trolley.

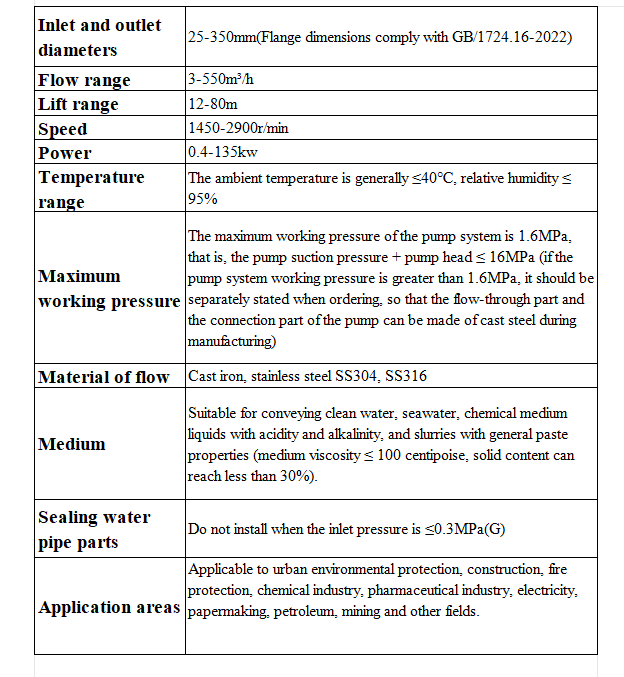

Working Conditions

Working Conditions

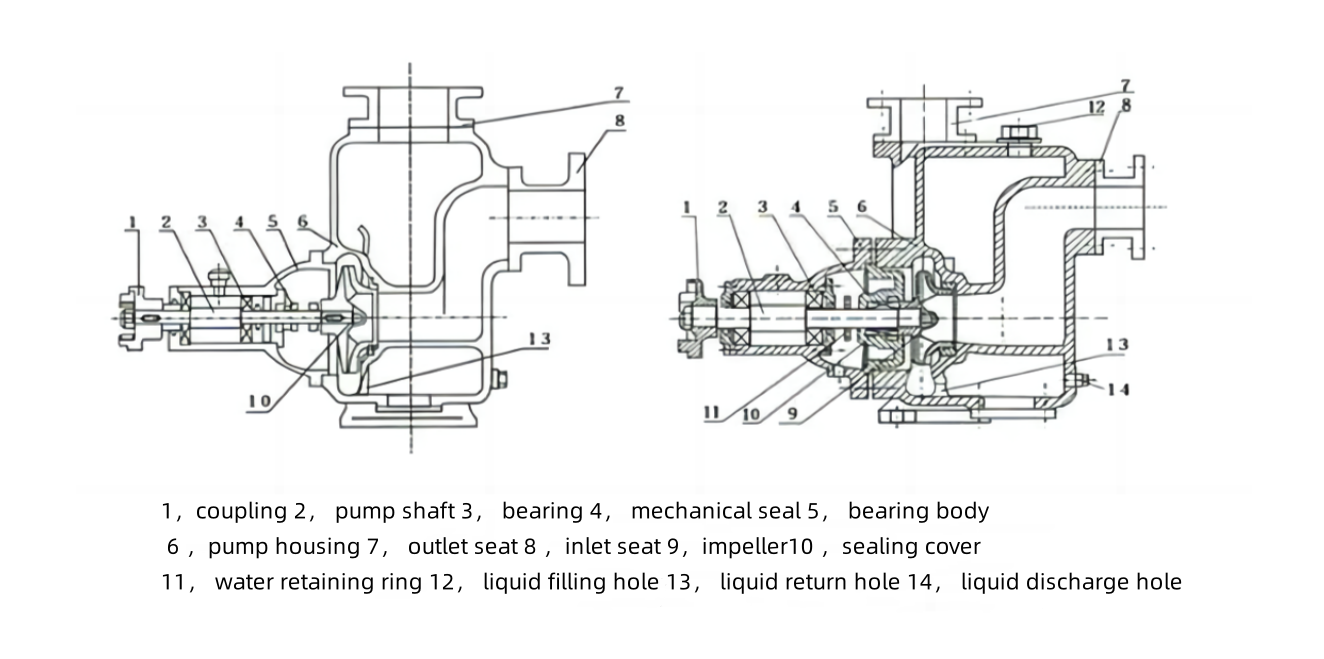

Product Structure Diagram

Product Structure Diagram

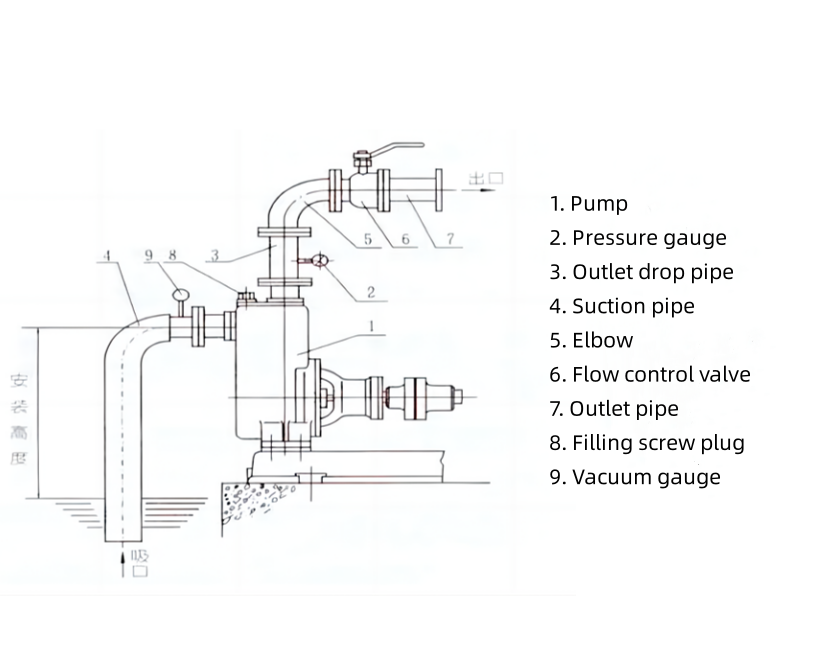

Installation dimension drawing

Installation dimension drawing

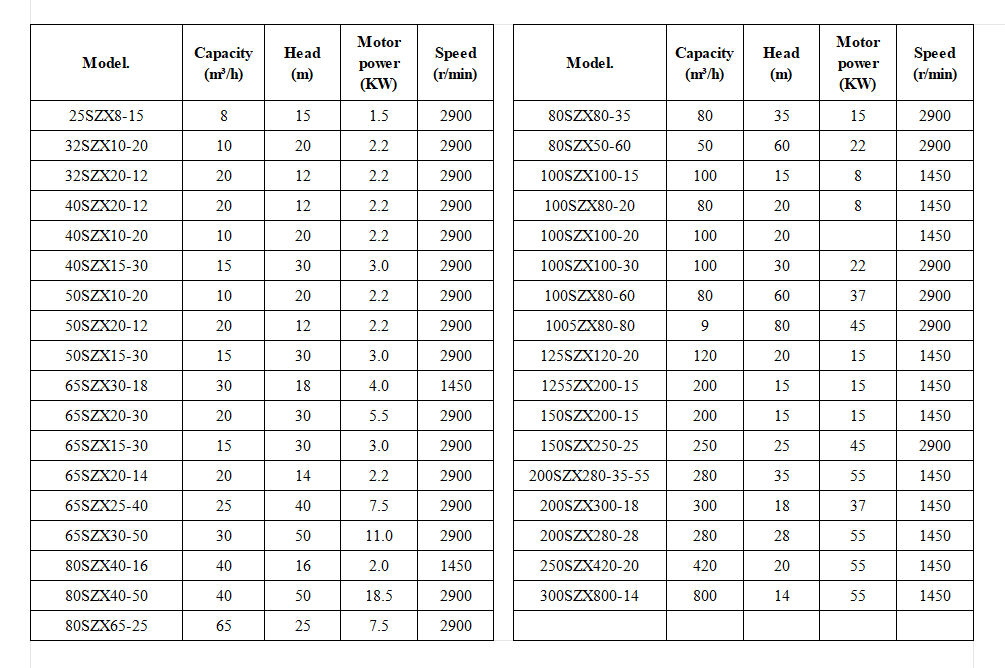

Performance parameters

Performance parameters

Types of Self-Priming Pumps

Positive Displacement Pumps

- Utilize pistons or diaphragms to move fluids precisely.

- Effective for handling viscous fluids or those containing solids.

Diaphragm Pumps

- Use flexible diaphragms to move fluids.

- Suitable for corrosive fluids or fluids with solids.

Horizontal Self-Priming Centrifugal Pumps

The horizontal self-priming centrifugal pump stands out for its robust design and ability to handle low-viscosity fluids like water or CIP solutions. It is particularly effective in situations where suction conditions are challenging.

Support and Services

We back our selfpriming centrifugal pump on trolley with comprehensive technical support and after-sales service. From tailored installation guidance and operational training to 24/7 troubleshooting, our expert team ensures your pump runs efficiently and reliably in any application.

Product Advantages about Shanglishi Energy-Saving Self-Priming Pumps

Powerful Self-Priming: The self-priming centrifugal pump uses advanced air discharge designs to rapidly evacuate air from the pump chamber and restore the negative pressure, ensuring continuous, efficient operation without manual intervention.

Energy Efficient: With an efficient impeller design, the pump delivers higher flow rates with lower energy consumption, reducing overall operating costs.

Simple Structure, Easy Maintenance: Unlike traditional pumps, the self-priming pump does not require a foot valve, suction pipe, or additional components, making installation straightforward. It also reduces the need for specialized technical support during maintenance.

Durable Construction: The pump body is made from high-quality cast iron, stainless steel, and alloys, offering excellent corrosion resistance, wear resistance, and oxidation protection. It is suitable for various harsh operating conditions and ensures a longer service life.

Wide Applicability: Whether for clean water, wastewater, chemical solutions, or liquids with impurities, the self-priming centrifugal pump performs excellently across various industries.Common Models and Selection Guidelines:

We offer a wide range of self-priming centrifugal pumps to meet different flow rate, head, and operational requirements. When selecting the appropriate model, consider the following factors:

Flow Rate: Choose a pump based on the required liquid transfer rate per hour.

Head Requirements: Select a model based on the required lifting height to ensure sufficient self-priming capability.

Liquid Characteristics: Consider the viscosity, corrosiveness, and gas content of the liquid to choose the right material and design.

Working Environment: Choose a model that can operate reliably in high temperatures, corrosive environments, or with liquids containing solid particles.Technical Support and After-Sales Service:

We not only provide high-quality self-priming centrifugal pumps but also offer comprehensive technical support and after-sales services:

Customized Solutions: We provide tailored pump solutions based on your specific application needs.

Installation Guidance and Training: We offer installation, debugging, and operational training to ensure seamless pump setup and usage.

24/7 After-Sales Support: Our professional after-sales team is available around the clock to ensure the efficient and stable operation of your equipment.The horizontal self-priming centrifugal pump is an indispensable solution for industries requiring efficient and reliable fluid transfer. Whether for industrial or sanitary applications, this self priming centrifugal pump ensures optimal performance and operational efficiency. Contact Shanglishi to choose the right pump for your needs and experience superior results today!

Industry Applications

Industry ApplicationsApplied to urban water supply system

Application in chemical industry

Application in power and electroplating industry

Applied to farmland irrigation

-

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP