SZP type slurry pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Introduction

Shanglishi SZP series slurry pump is a new type of high efficiency and energy saving anti-wear pump. This series of pumps in hydraulic design, structural design and wear-resistant materials used, the comprehensive application of the advantages of similar products at home and abroad and to be innovative, with high efficiency and energy saving, low vibration, low noise, reliable operation, long service life, convenient maintenance and other characteristics, the comprehensive performance of the pump in the domestic leading level, most of the pump efficiency indicators in the international advanced level. It can be widely used in electric power, metallurgy, coal, building materials and other industries to transport slurry containing solid particles. Such as hydraulic ash removal in thermal power plants, slurry transportation in metallurgical ore dressing plants, coal slurry and heavy medium transportation in coal washing plants. The maximum slurry weight concentration allowed to be transported is: ash (slag) slurry and coal slurry 45%; The slurry is 60%, and the medium temperature is ≤ 60 ℃.

Key Features of the SZP Series Single Stage Single Suction Centrifugal Pump

Internal and External Bimetallic Structure: The SZP series single stage single suction centrifugal pump features an internal and external bimetallic design. The outer pump shell is made of ductile cast iron, while the inner shell is constructed from high-chromium anti-wear cast iron or cast steel. This structure enhances the pump's durability and reduces operating costs.

High Efficiency and Energy Saving: Shanglishi sewage slurry mud pump is designed using modern fluid mechanics and mechanical design technologies. With innovations in hydraulic and structural design, it reduces power consumption by approximately 5% compared to traditional pumps, delivering excellent energy-saving performance.

Multiple Shaft Sealing Methods: The pump offers three different shaft sealing methods: packing seal, impeller seal, and mechanical seal. Each method is selected based on the specific working conditions, ensuring stable operation of the single stage single suction centrifugal pump.

Wide Industrial Adaptability: The SZP series sewage slurry mud pump is suitable for various industries such as electricity, metallurgy, coal, building materials, and chemicals. It is capable of handling abrasive or corrosive slurries containing solid particles, with a slurry concentration of up to 45%. It can also operate in temperatures up to 60°C and be used in multi-stage applications.

Rotatable Pump Body: The pump shell features a vertical open-type outlet that can be rotated to eight different positions at 45° intervals, allowing for easy installation and maintenance of the single stage single suction centrifugal pump.

Comprehensive Product Model Range: The SZP series single stage single suction centrifugal pump is available in both horizontal and vertical designs. Horizontal models range from 350mm to 40mm in outlet diameter, with different impeller sizes to match specific head requirements, offering strong product selectivity and a wide range of options.

This combination of durability, energy efficiency, and adaptability makes the SZP series a top choice for various demanding industrial applications.

Working conditions

Maximum flow rate: 2339 m/h

Maximum lift: 129m

Speed: 720,990,1480 and 2960r/min

Medium: medium containing higher solid particles

Caliber: 40mm-350mm

Material: cast iron, high chromium alloy, rubber, etc

Product Structure Characteristics

The type of SZP series slurry pump is divided into two categories, one is SZP type, which is a horizontal axial suction single-stage single-suction centrifugal slurry pump; the other is SZPL type, which is a vertical axial suction single-stage single-suction centrifugal slurry pump.

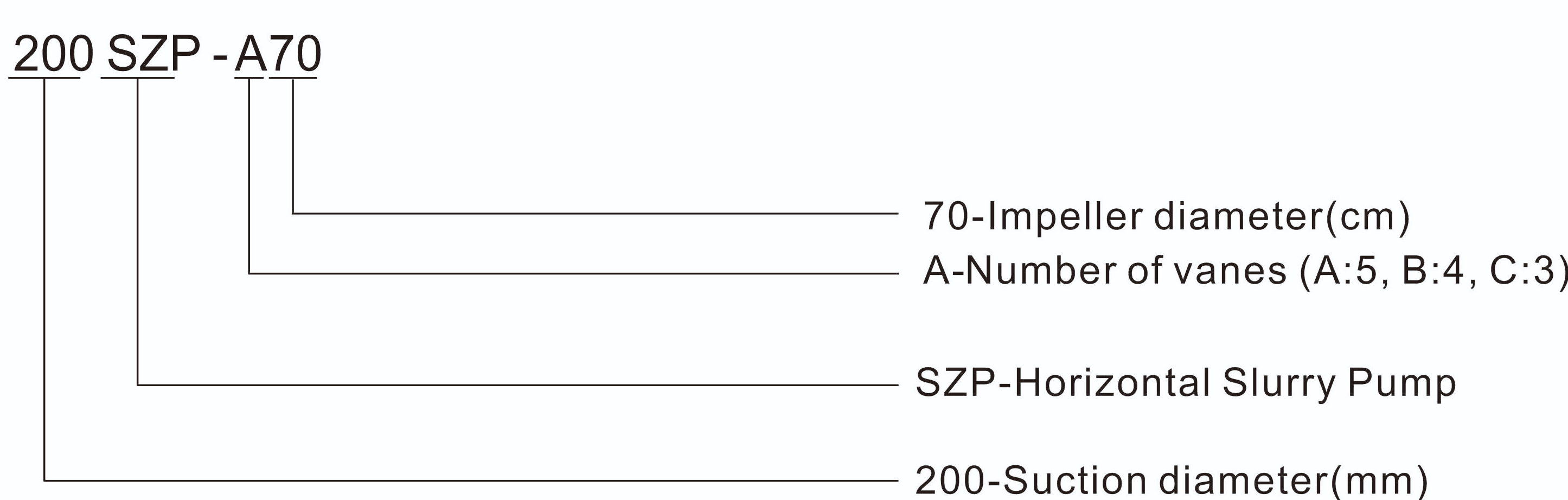

(1) Structural characteristics of SZP type slurry pump Model and Significance of SZP Slurry Pump

Model and Significance of SZP Slurry Pump

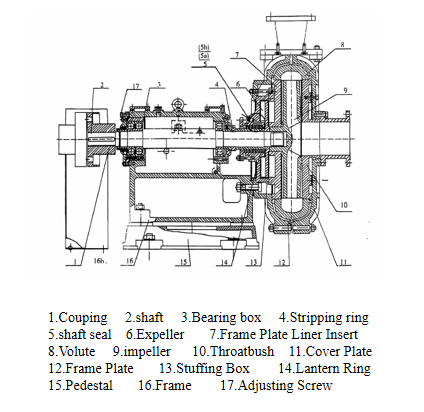

① Pump head

The pump head part of SZP slurry pump includes pump casing, impeller and shaft seal device. Our single stage single suction centrifugal pump head and the bracket are connected with bolts. According to the needs, the outlet position of the pump can be rotated at 45 ° intervals to eight different angles to install and use.

The pump casing of SZP slurry pump is of double shell structure. The outer layer is a metal pump casing (front pump casing, rear pump casing), and its material is usually HT200 or QT500-7; the inner shell can be made of high chromium alloy cast iron (including volute, front guard plate, rear guard plate), or Made of rubber (including front volute and rear volute)

The impeller is composed of front cover plate, rear cover plate, blade and back blade. The blades are twisted blades, usually 3-6. The back blades are distributed on the outside of the front cover plate and the rear cover plate, and there are usually 8 blades. The material of the impeller is high chromium alloy cast iron, and the impeller and the shaft are threaded connection.

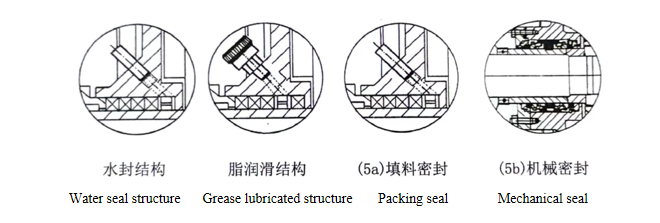

The shaft seal device has three types: auxiliary impeller packing combination seal, packing seal and mechanical seal.

The combined sealing type of auxiliary impeller and packing is composed of stuffing box, auxiliary impeller, water seal ring, packing, packing gland and shaft sleeve.

The packing seal type is composed of packing box, spacer sleeve, water seal ring, packing, packing gland and shaft sleeve, as shown in Fig. 5a.

The mechanical seal type consists of stuffing box, spacer sleeve, mechanical seal, gland and shaft sleeve, as shown in Fig. 5b.

② Bracket part

The bracket part has two structures: horizontal middle opening type and cylinder type.

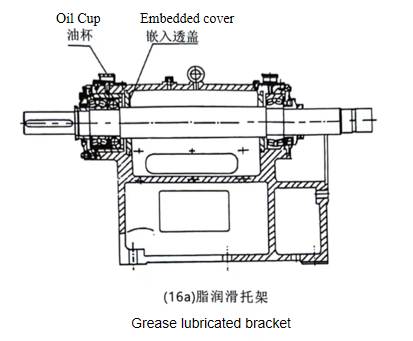

Open bracket with thin oil lubrication and grease lubrication of two types. The thin oil lubrication bracket is mainly composed of bracket body, bracket cover, shaft, bearing box, bearing, bearing gland, stop sleeve, nut, oil seal, water retaining plate, disassembly ring and other parts, as shown in Figure 1. 150SZP and above pump type also with water cooling device. The main difference between the grease lubrication bracket and the thin oil lubrication bracket is that the embedded through cover and oil cup are added, and the water cooling device is removed, as shown in Figure 16a.

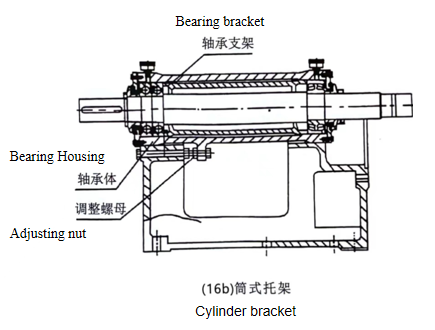

The cylindrical brackets are all lubricated with grease and are mainly composed of bracket body, bearing body, shaft, bearing, bearing top sleeve, bearing gland, oil seal, oil cup, water retaining plate, disassembly ring and other parts, as shown in Figure 16b. Cylinder bracket is only suitable for 200SZP and the following power smaller pump type, currently only T200SZP-I-A70, T200SZP-I-A60, T150SZP-I-A60 three specifications.

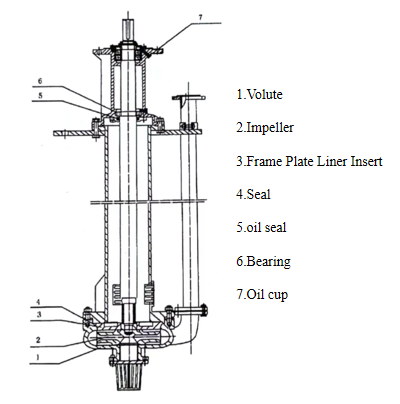

(2) the structural characteristics of SZPL type slurry pump

① SZPL slurry pump is mainly composed of impeller, volute, rear guard plate, shaft sleeve, bracket, support plate, shaft, bearing, bearing body and other parts. The material of the impeller, volute and rear guard plate is high chromium alloy cast iron. The impeller and the shaft are connected by threads, and the volute, bracket and bearing body are connected by bolts. The pump shaft and motor can be driven by coupling direct connection or belt drive. The bearings of SZPL pumps are lubricated with grease. This series of pumps are non-shaft seal pumps.

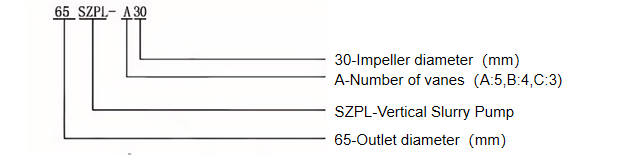

② Model and significance of SZPL slurry pump

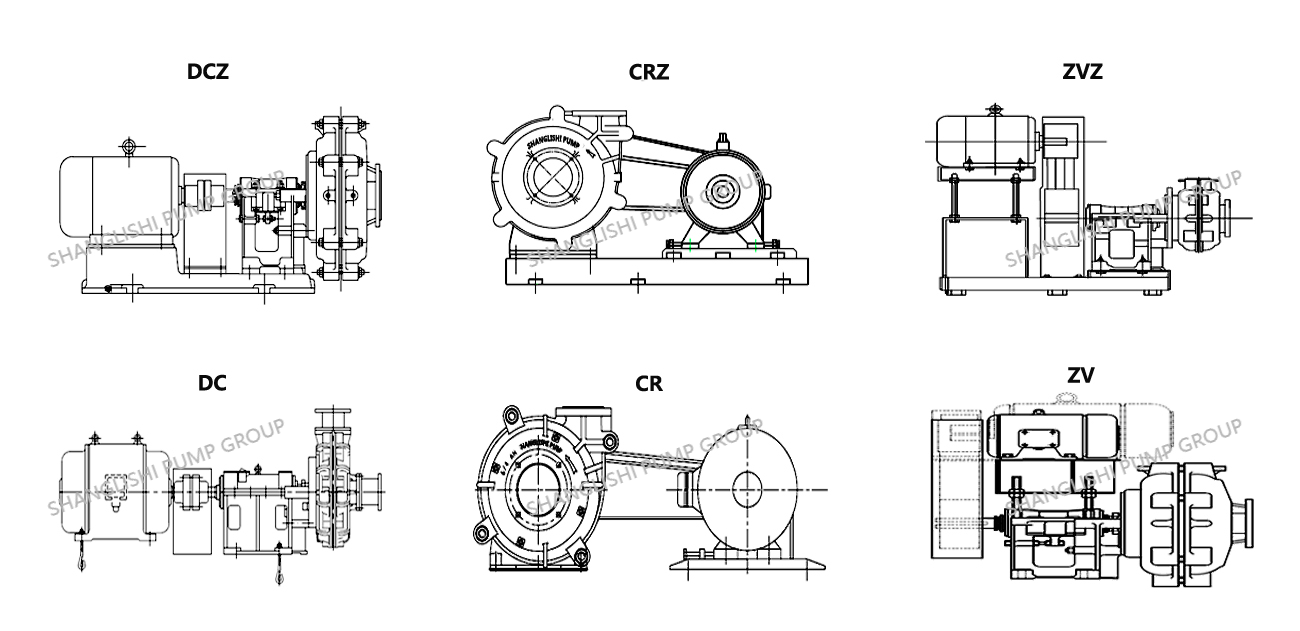

Transmission mode

SZP series slurry pump is a high-efficiency energy-saving, single-stage, single-suction, centrifugal slurry pump developed by our company. Horizontal pump (SZP type) according to the outlet diameter is divided into 450mm, 400mm, 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, 40mm and other specifications. Vertical pump (SZPL type) according to the outlet diameter is divided into 150mm, 100mm, 80mm, 65mm, 50mm and other specifications. The series of slurry pump in the hydraulic design, structural design has innovation, flow components using self-developed anti-strong wear-resistant alloy cast iron manufacturing. It has the remarkable characteristics of high efficiency, energy saving, long service life, light weight, reasonable structure, reliable movement, low vibration, low noise, and convenient maintenance.

Our series of pumps have wide performance range, good cavitation performance and high efficiency. Multi-stage series technology can be used to meet long-distance transmission. The flow components are available in a variety of metals and are increased in depth. The use of a variety of speed and a variety of variants, so that the pump in the best mining operation. Long service life, high operating efficiency, can meet many types of harsh transportation conditions.

Selection Guidelines

When selecting a sludge pumps wastewater treatment pump, consider the following factors:

Required flow rate and head: Ensure that the single stage single suction centrifugal pump's performance parameters align with the specific application requirements.

Characteristics of the medium: Consider factors such as temperature, viscosity, and corrosiveness to choose the appropriate materials and sealing methods.

Installation space: Take into account the sewage slurry mud pump's dimensions, weight, and site conditions for optimal placement.Maintenance and Care

Regular inspections: Periodically check the seals, bearings, and pump body for wear or leaks.

Lubrication: Regularly lubricate the bearings to ensure smooth operation.

Prevention of dry running: Ensure that the pump casing is filled with liquid before starting to avoid damage from dry running.

Cleaning and upkeep: Regularly clear debris from the pump to prevent clogging and ensure efficient performance.Industry Applications

The single stage single suction centrifugal pump is widely used in the following areas:

Industrial production: It is commonly used in sectors such as chemical processing, petroleum, power generation, and paper manufacturing for cooling, circulation, and drainage applications.

Municipal engineering: Ideal for urban water supply, sewage treatment, and water management projects.

Agricultural irrigation: Suitable for farm irrigation and well water extraction.

Building water supply: Often utilized in high-rise buildings to boost water pressure in pumping systems.Electric power industry slurry pump

Metallurgical industry slurry pump

Coal industry slurry pump

Building materials industry slurry pump

Chemical industry slurry pump

Mining industry slurry pump

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including:ChinaHuadian,ChinaDatang Group, Datang International,ChinaHuaneng,ChinaState Investment,ChinaGuodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel, Yanshan Iron and Steel, Jiujiang Wire, Jiujiang Pinggang, Donghai Special Steel, etc.

Application of Slurry Pump in Electric Power and Other Industries

Application of slurry pump in metallurgy and other industries

Application of slurry pump in coal and other industries

Application of slurry pump in building materials and other industries

Application of slurry pump in chemical industry

Application of slurry pump in mine

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP