Slurry Pump Accessories

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Introduction

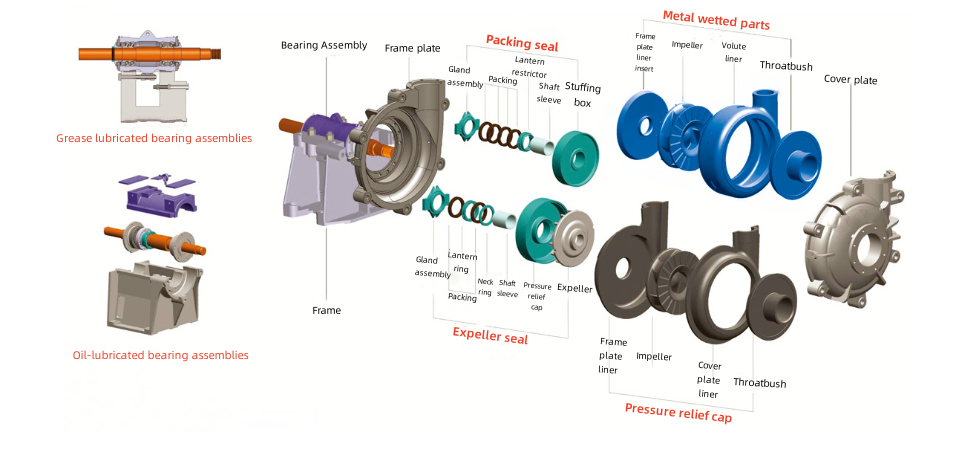

Product IntroductionShanglishi Slurry pump is mainly divided into three parts: pump head part, shaft seal part, bracket part.

The first is the pump head part, mainly: pump body, pump cover, sheath, front guard plate, rear guard plate, impeller. In addition to the pump body cover, the others are all over-current parts, made of high chromium alloy, or natural rubber, and can also be specially customized.

Followed by the shaft seal part: the shaft seal is mainly divided into three forms, one is the packing seal, two decompression cover vice impeller seal, three is the mechanical seal.

Packing seal is composed of: shaft sleeve, front water seal ring, stuffing box, packing gland, packing, positioning sleeve; decompression cover vice impeller seal is composed of: shaft sleeve, water seal ring, decompression cover, vice impeller, packing, positioning sleeve. The composition of mechanical seal is: moving ring, static ring, mechanical seal components, sealing ring.

Finally, the bracket part is composed of: bracket and bearing assembly. The bearing assembly is composed of shaft, bearing, labyrinth sleeve, labyrinth ring, end cover, etc.

We can customize all the components of the slurry pump for you and provide solutions according to your needs.

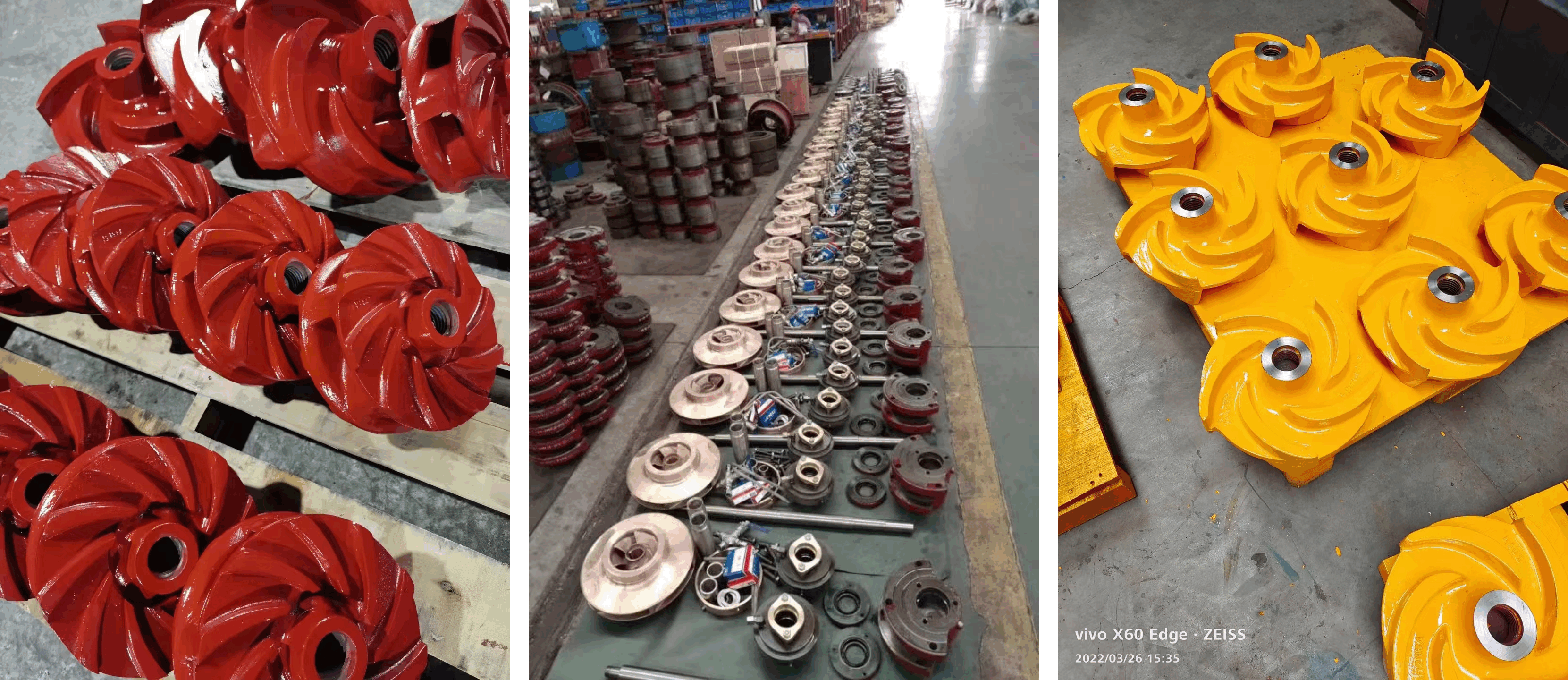

Comprehensive Range of Slurry Pump Accessories

Pump Impellers

Types: Closed, semi-open, open, and vortex designs tailored for various slurry types.

Key Advantage: Reduces wear by up to 30% with improved flow dynamics.

Liners and Casings

Material Options: Elastomer, metal, and ceramic composites for different slurry applications.

Custom Designs: Engineered to handle flow rates and particle sizes specific to your operations.

Bearings and Frames

Performance: Designed to withstand heavy radial loads and extreme vibration.

Feature: Advanced lubrication systems for reduced friction and wear.

Sealing Systems

Variety: Includes mechanical seals, expeller rings, and packing seals.

Advantages: Leak-proof designs that ensure environmental safety and pump longevity.

Shaft Sleeves

Protects pump shafts from wear and corrosion, extending the overall service life of the pump.

Structural Breakdown

Structural Breakdown

Shanglishi Slurry Pump Accessories - The Key to Improving Pump Performance

The performance and service life of a slurry pump largely depend on the quality of its accessories. We provide high-quality slurry pump accessories to help your pump perform at its best.

1. High-quality materials

Our slurry pump accessories are made of high-quality wear-resistant materials such as high-chrome alloy, natural rubber, synthetic rubber, polyurethane and ceramic. No matter how harsh your working conditions are, we can provide the right solution.

2. Excellent wear resistance

Our slurry pump accessories are carefully designed and strictly controlled for excellent wear resistance. Even in highly abrasive environments, they can significantly extend service life and reduce maintenance costs.

3. Perfect compatibility

Our accessories are fully compatible with mainstream slurry pump models. They can be installed and used directly without modifying the original equipment. Ensure fast replacement and minimize production interruptions.

4. Reliable supply

We have a rich inventory of spare parts to ensure that you can meet your needs at any time. At the same time, we also provide fast delivery services so that your production will not be affected by the lack of spare parts.

5. Professional support

Our technical team is always available to provide you with professional advice. Recommend the best slurry pump accessories solution for you according to your specific situation. Let you use our products with peace of mind.

Choose our slurry pump accessories to make your pump perform at its best and improve production efficiency. For more information, please feel free to contact us. Summary of Wear Mechanism of Flow Parts of Slurry Pump

Summary of Wear Mechanism of Flow Parts of Slurry PumpSlurry pump flow parts wear mechanism summary, slurry pump wear involves many factors, and different parts and different parts of the wear mechanism is not the same, but in general can be summarized into three categories:

1. erosion wear

- 1. Erosion wear During the operation of the slurry pump, the solid particles carried in the liquid impact the flow parts at a certain speed, causing material loss.

- 2. According to the analysis of the wear table of failed parts, erosion wear can be divided into cutting wear, deformation fatigue wear and cutting deformation composite wear.

2. cavitation wear

- 1. Cavitation damage of slurry pump During the operation of the pump, for some reason, when the absolute pressure of the pumped liquid drops to the vaporization pressure at the current temperature, the liquid will start to vaporize at the local area of the over-flow component, usually the liver at the inlet of the impeller, generating steam and forming bubbles.

- 2. These bubbles flow forward with the liquid. When they reach a certain high pressure, the bubbles shrink sharply and even collapse. At the same time as the bubbles condense, the liquid particles fill the pores at a high speed and have a strong impact on the metal surface. The metal surface is fatigued and peeled off due to this impact, resulting in material loss. In severe cases, the metal surface appears honeycomb. Usually cavitation occurs at the impeller outlet and volute inlet.

3. corrosion and wear

- 1. Corrosive wear When the transported medium has a certain pH, the flow-passing parts of the slurry pump will also undergo corrosive wear, that is, the phenomenon of material loss under the combined action of corrosion and wear.

- 2. Corrosion can be divided into chemical corrosion and electrochemical corrosion: chemical corrosion is the loss of metal caused by the direct reaction of metal and liquid medium;

- 3. Electrochemical corrosion is the loss of materials caused by the formation of micro batteries on the metal surface under the action of liquid medium.

Custom Manufacturing: Tailored to Your Needs

One of the core strengths of our slurry pump accessories is our ability to provide fully customizable solutions. Using advanced CNC machining and CAD technology, we design components to meet precise operational requirements.

Case Study:

A gold mining company required customized impellers to handle high-density slurry with large particle sizes. By optimizing the impeller blade geometry and using a high-chrome alloy, we increased their pump efficiency by 18% and reduced downtime by 25%.

Part Number List

Number Part Name Basic Part Number Part Name Basic Part Number 1

butterfly screw 001 Impeller / Base 003 Inlet fitting ring 060 Bearing box 004 Labyrinth Lock Nuts and Washers 061 Bearing assembly 005 Labyrinth 062 Bearing 009 Lantern Ring 063 Clamp washer 011 Impeller O-ring 064 Clamping bolts and nuts 012 Neck ring 067 Cover 013 Axis Key 070 Cover bolt 015 Shaft 073 Cover pad 017/018 Shaft sleeve 075/076 Cover Pad Dirt 023 stuffing box 078 End cap 024 retainer plate 081 End cover gasket 025 Throat bushing 083 Frame plate insert stud 026 Throat sleeve cotton 085 End cap retaining screw 027 Seal 089/090 oil press 028 Piston ring 108 Oil press ring 029 Shaft O-ring 109 FRAME PLATE 032 volute liner 110 Frame plate bolts 034 Packing ring 111 Frame plate gasket 036 Shaft Gasket 117 Frame plate interlining nail 039 Lantern Limiter 118 Frame plate lining insert bolt 040 Pusher ring seal 122 Frame plate bushing 041 Volute cover seal 124 Frame plate gasket 043 Spiral case frame seal 125 Gland 044 gland clamp bolt 126 Packing gland bolt 045 Splice Ring Drain 132 Retaining ring 046 Grease Cup Adapter 138  Industry Applications

Industry Applications electric power industry slurry pump accessories

mining industry slurry pump accessories

coal industry, coal chemical industry slurry pump accessories

dredging river slurry pump accessories

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP