STL Series Desulfurization Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Introduction

Wet Desulfurization Pump: Advanced Industrial Desulfurization Pump for FGD Applications

Industrial Desulfurization Pump technology represents the cutting edge of slurry handling systems, engineered for high efficiency, energy saving, and long service life. As a renowned Desulfurization Pump Manufacturer & Supplier known among leading FGD Pumps users, Shanglishi delivers outstanding performance in diverse industrial applications.

Our STL Series Desulfurization Pump features both horizontal and vertical (liquid) configurations, integrating innovative hydraulic and structural design with wear-resistant materials. Designed to transport slurry containing solid particles, this pump is ideal for electric power, metallurgy, coal, building materials, and other industries.

Horizontal, vertical (liquid) series of desulfurization pump in the hydraulic design, structural design and the use of wear-resistant materials, the comprehensive application of the advantages of similar products at home and abroad and to be innovative

Shanglishi desulfurization pump has the characteristics of high efficiency and energy saving, low vibration, low noise, reliable operation, long service life, and convenient maintenance. The comprehensive performance of the pump is at the leading level in China, and the efficiency index of most pumps is at the international advanced level.

The maximum slurry weight concentration Cw allowed to be transported is: ash (slag) slurry and coal slurry 45%; Mineral slurry and heavy medium 60%.

Why Choose Shanglishi as Your Desulfurization Pump Manufacturer & Supplier?

-

Mobility and Versatility: With a four-wheel design, the horizontal model offers ease of movement and flexible installation, while the vertical model is optimized for axial suction.

-

Dual-Function Technology: Our STM series combines rib stripping and thread rolling in one clamping operation, minimizing handling and increasing productivity.

-

Durability and Maintenance: Constructed with high chromium alloy cast iron, HT200, or QT500-7 materials, the pump is built for long-term operation and convenient maintenance.

-

Robust Performance: Designed to work under various weather conditions, this Industrial Desulfurization Pump ensures stable performance with low vibration, low noise, and energy-efficient operation.

Working Conditions

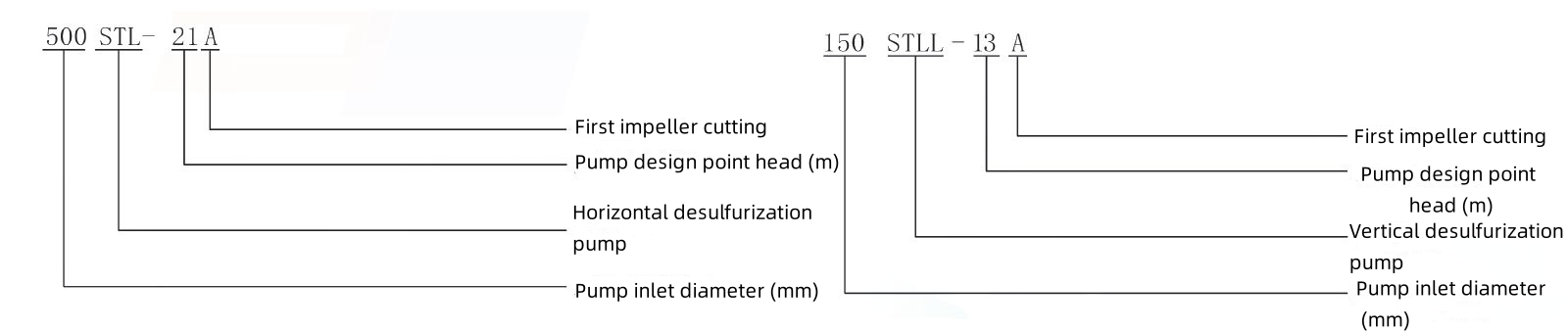

Inlet and outlet diameter 25-900mm Flow range 600-25000m³/h Lug range 20-150 Speed 720,990,1480 and 2960r/min Power 300-5000KW Structural Design The pump is axial suction, single stage, single suction, cantilever centrifugal structure. Application areas Widely used in thermal power plants, aluminum smelting plants and oil refineries and other industries desulfurization system conveying limestone or gypsum slurry Medium Conveying corrosive media containing fine particles Material classification high chromium alloy Model Meaning

Product Features

Product FeaturesThe STL Series Desulfurization Pump is divided into two categories, one is horizontal, for the axial suction single-stage single suction centrifugal desulfurization pump, another is vertical, single-stage single-suction centrifugal desulfurization pump for vertical axial suction.

1.Structural features and models of horizontal desulfurization pumps

(1)Structural characteristics of horizontal desulfurization pump

Pump head section

The STL Series Desulfurization Pump head portion includes a pump casing, an impeller, and a shaft seal device. The pump head is bolted to the bracket. According to the need, the position of the outlet of the pump can be 45° Interval rotation is used for eight different angle mounting.

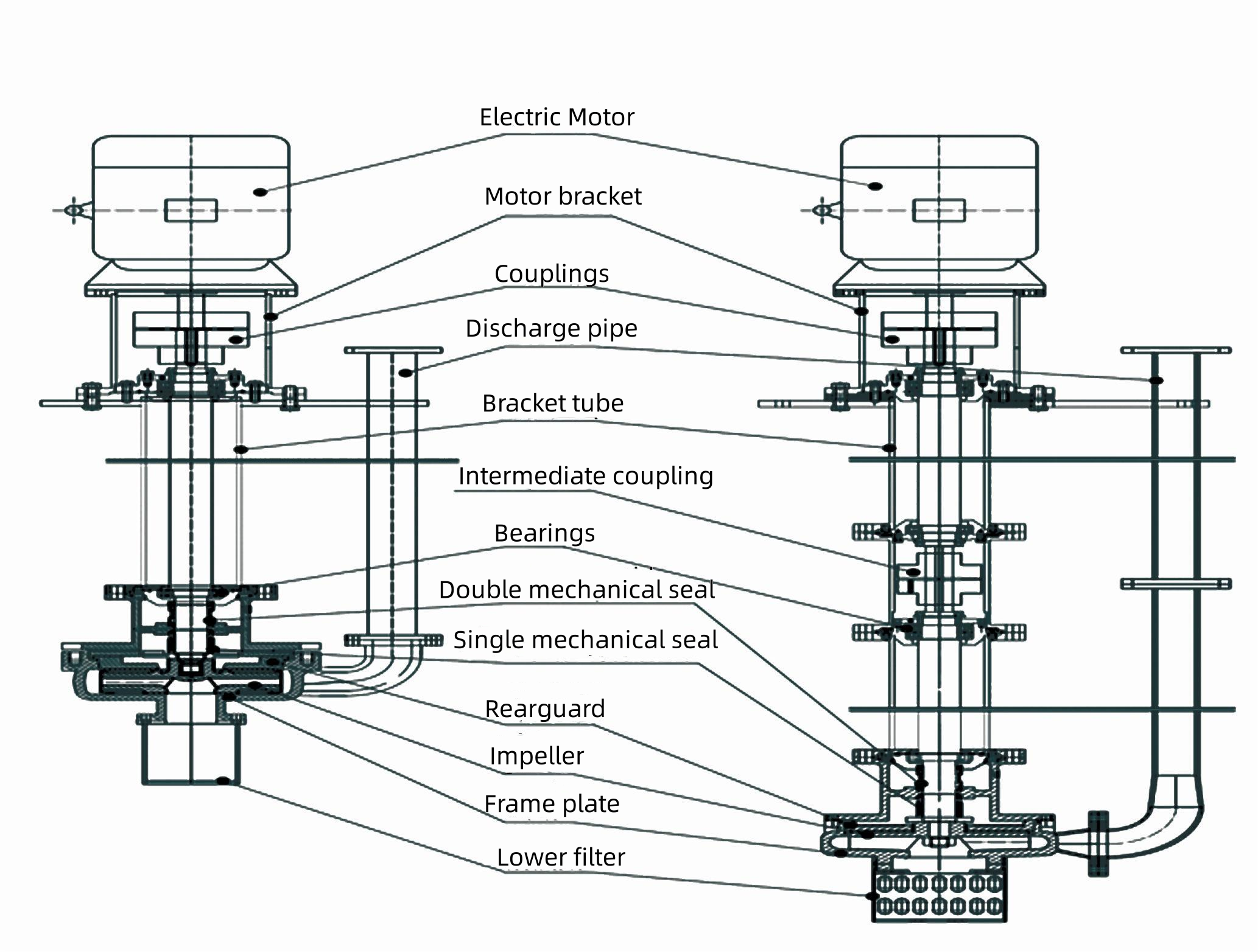

The Shanglishi Wet Desulfurization Pump shell of this series of desulfurization pump has both double-layer shell structure and single-layer shell structure. The outer layer of the double-layer structure is the metal pump shell (Front pump casing, rear pump casing),The material is usually HT200 or QT500-7. The inner shell can be made of wear-resistant and corrosion-resistant high-chromium alloy cast iron.(Including volute, front guard and rear guard), or made of rubber (Including front volute and rear volute).

The impeller is composed of front cover plate, rear cover plate, blade and back blade. The blades are twisted blades and usually have 3-6 pieces. The back blades are distributed on the outside of the front and rear cover plates, usually 8 pieces. The material of the impeller is high chromium alloy cast iron, and the impeller and the shaft are threaded connection.

Shaft seal device with auxiliary impeller+Packing combination seal, packing seal, mechanical seal three types.

Vice impeller+Packing combination sealing type consists of stuffing box, auxiliary impeller, water seal ring, packing, packing gland and shaft sleeve.

Packing seal type consists of stuffing box, spacer sleeve, water seal ring, packing, packing gland and shaft sleeve. The mechanical seal type consists of a sealing box, a spacer sleeve and a mechanical seal.Bracket section

The bracket part has two structures: horizontal middle opening type and cylinder type.

Open bracket with thin oil lubrication and grease lubrication of two types. The thin oil lubrication bracket is mainly composed of bracket body, bracket cover, shaft, bearing box, bearing, bearing gland, stop sleeve, nut, oil seal, water retaining plate, disassembly ring and other parts. The larger diameter pump also has a water cooling device. The cylindrical brackets are lubricated with grease and are mainly composed of bracket body, bearing body, shaft, bearing, bearing top sleeve, bearing gland, oil seal, oil cup, water retaining plate, and other parts.

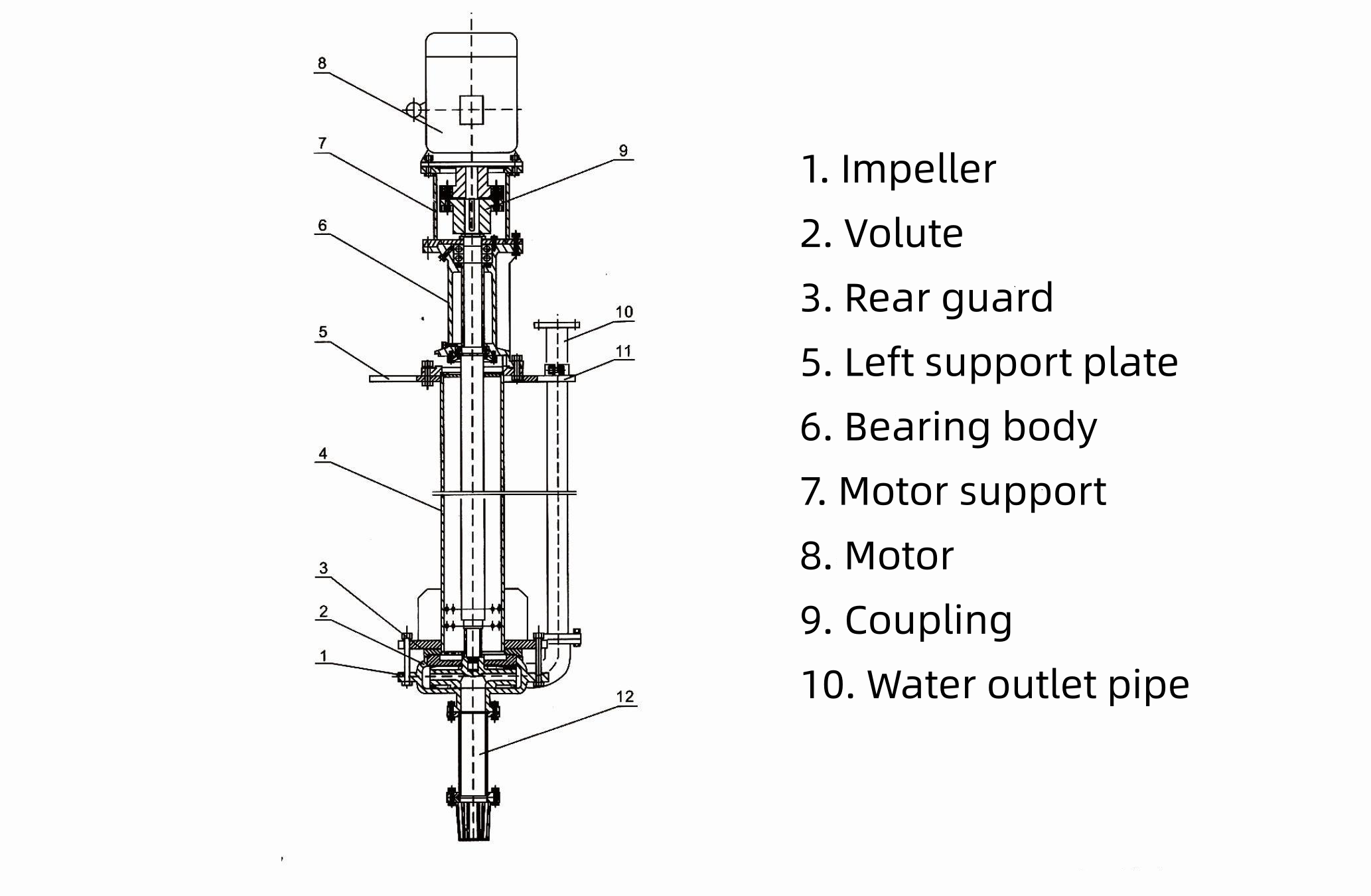

2. Vertical (liquid) desulfurization pump structure features and models

(1) Structural features

Vertical desulfurization pump is mainly composed of impeller, volute, rear guard plate, shaft sleeve, bracket, support plate, shaft, bearing, bearing body and other parts. The material of the impeller, volute and rear guard plate is high chromium alloy cast iron. The impeller and the shaft are connected by threads, and the volute, bracket and bearing body are connected by bolts. The pump shaft and motor can be driven by coupling direct connection or belt drive. The bearings are lubricated with grease.

(2) No shaft seal, hanging wall type vertical (liquid) desulfurization pump structure diagram

(3) Mechanical seal, extended vertical (liquid desulfurization pump structure diagram

Structural Design and Components

Shanglishi Wet Desulfurization Pump head assembly comprises a casing, impeller, and shaft seal device, with options for double-layer or single-layer shells. The horizontal model allows for outlet rotation in 45° intervals for versatile installation, while the vertical model features a streamlined design with secure bolt connections. Multiple shaft seal options—auxiliary impeller with packing, packing seal, or mechanical seal—further enhance its reliability.

Quality, Safety, and Reliability

Engineered to meet international standards, our Industrial Desulfurization Pump excels in efficiency and operational safety. Its advanced cooling system, protective guards, and emergency stop mechanisms ensure optimal performance even in harsh industrial environments. Recognized as a benchmark among FGD Pumps, this pump’s comprehensive design delivers both high productivity and minimal maintenance downtime.

Shanglishi Industrial Desulfurization Pump is a state-of-the-art solution that combines innovative design, robust materials, and energy-efficient performance for critical slurry handling tasks. Trusted by top industry players and available from a leading Desulfurization Pump Manufacturer & Supplier, this pump is essential for wet desulfurization applications. Choose our FGD Pump to enhance your operations and experience reliable, high-performance service—your ideal solution in industrial slurry transportation and beyond, delivered by an expert provider of Industrial Desulfurization Pump technology.

Industry Applications

Industry Applications

Shanglishi Industrial Desulfurization Pump is extensively used in wet desulfurization systems for thermal power plants, hydraulic ash removal, metallurgical ore dressing, coal washing, municipal sewage disposal, and river dredging. It is engineered to handle slurry with weight concentrations of up to 45% for ash or coal slurry, and up to 60% for mineral slurry and heavy mediums.

Desulfurization Pump in Fine Chemical Industry

Desulfurization Pump in the Energy Industry

Desulfurization Pump in Non-Ferrous Metal Smelting Industry

Desulfurization Pump in Water Treatment Industry

Desulfurization Pump Used in Coal Industry, Coal Chemical Industry

Desulfurization Pump in Chlor-Alkali Industry

Desulfurization Pump in Chemical Industry

Desulfurization Pump in Steel Industry

-

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP