SG Series Gravel Pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

Product Introduction

The Shanglishi gravel pump is designed for efficient transportation of strong abrasive materials that are typically too large for standard slurry pumps. This pump features a single-stage, single-suction, cantilever, horizontal structure, making it versatile across various applications such as coal, electricity, river dredging, and municipal engineering.

Gravel Pump Design and Structure

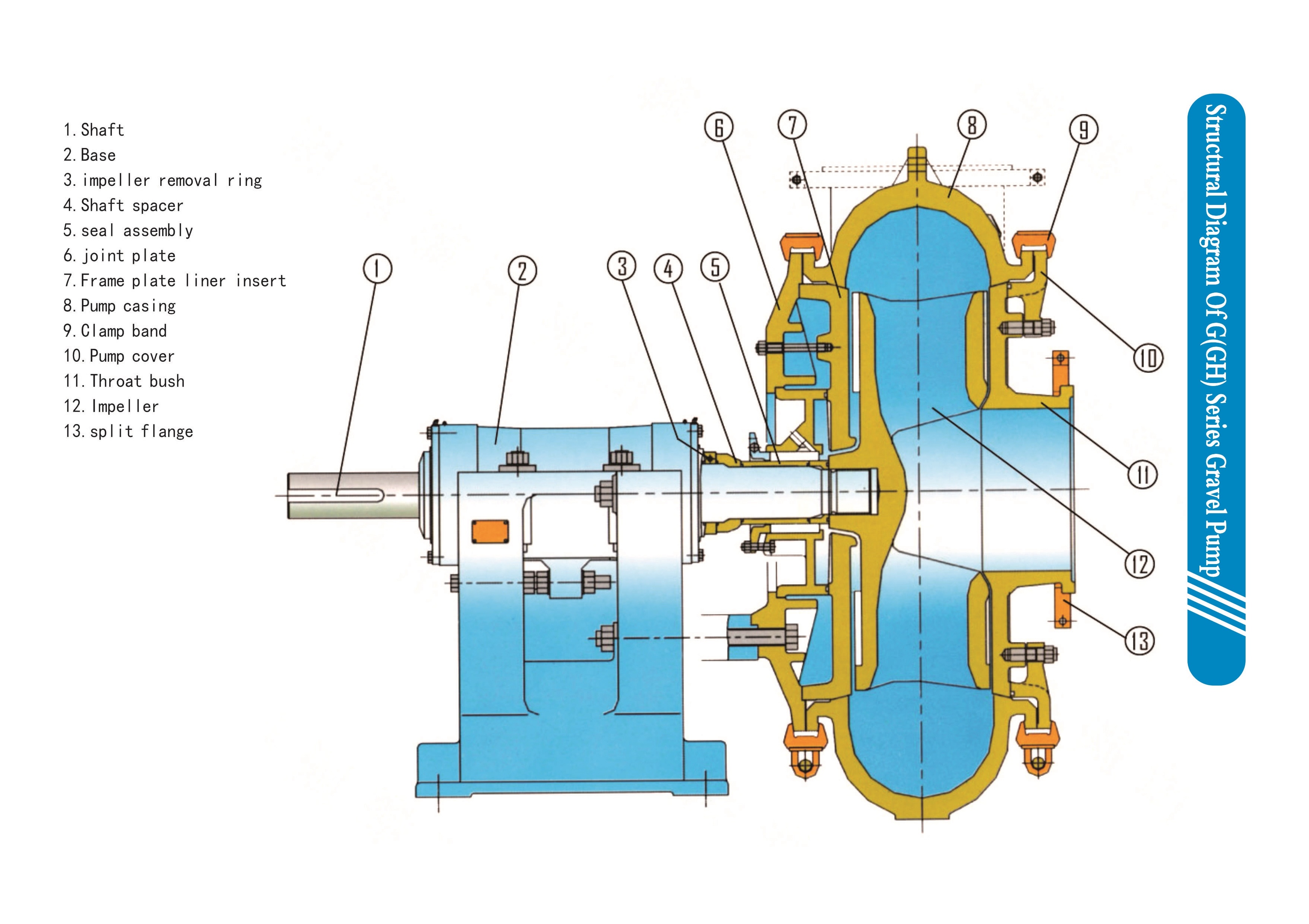

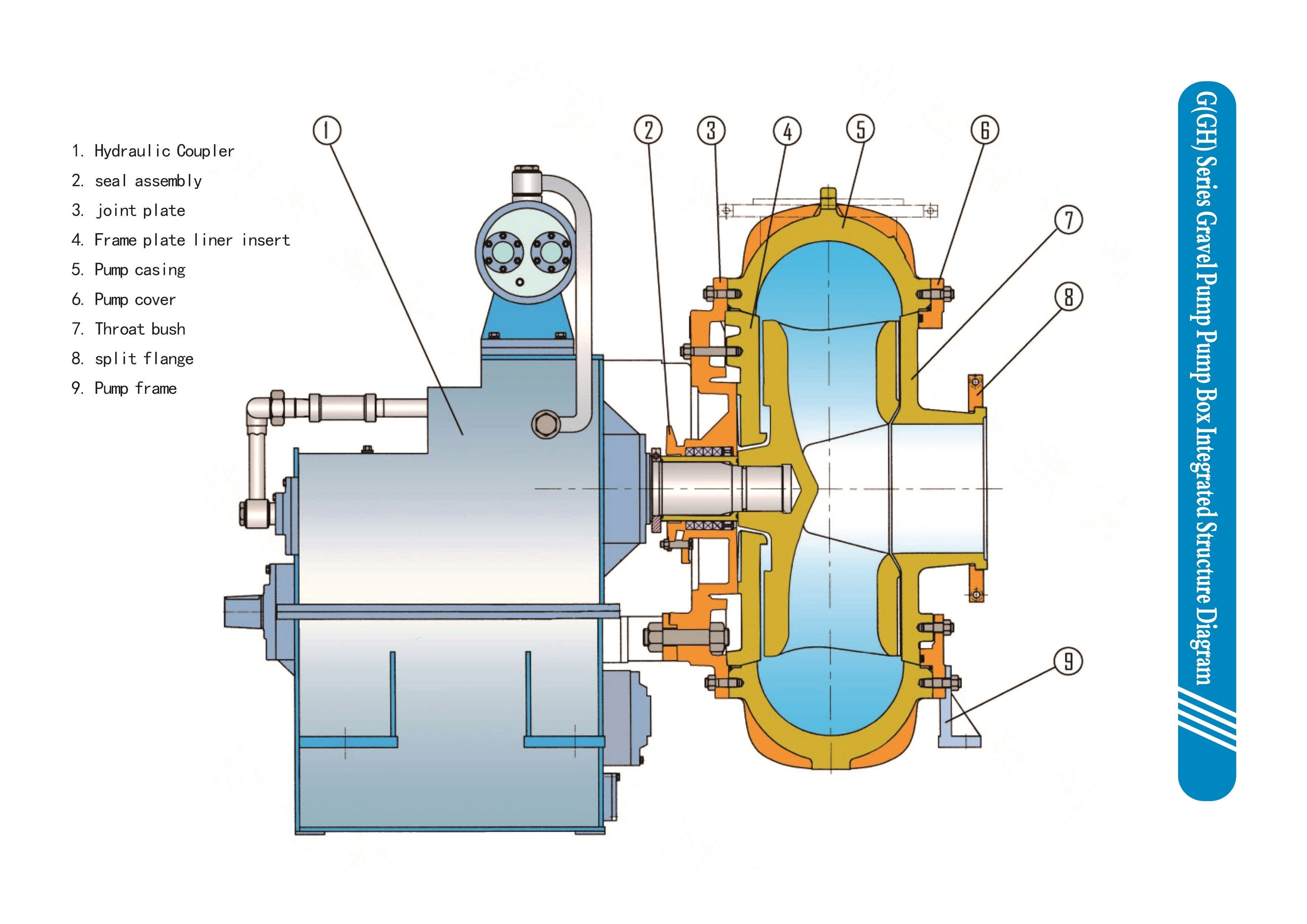

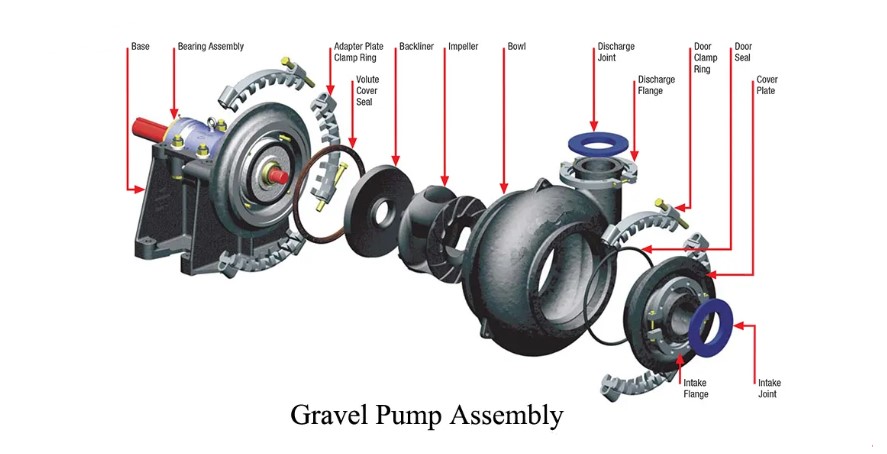

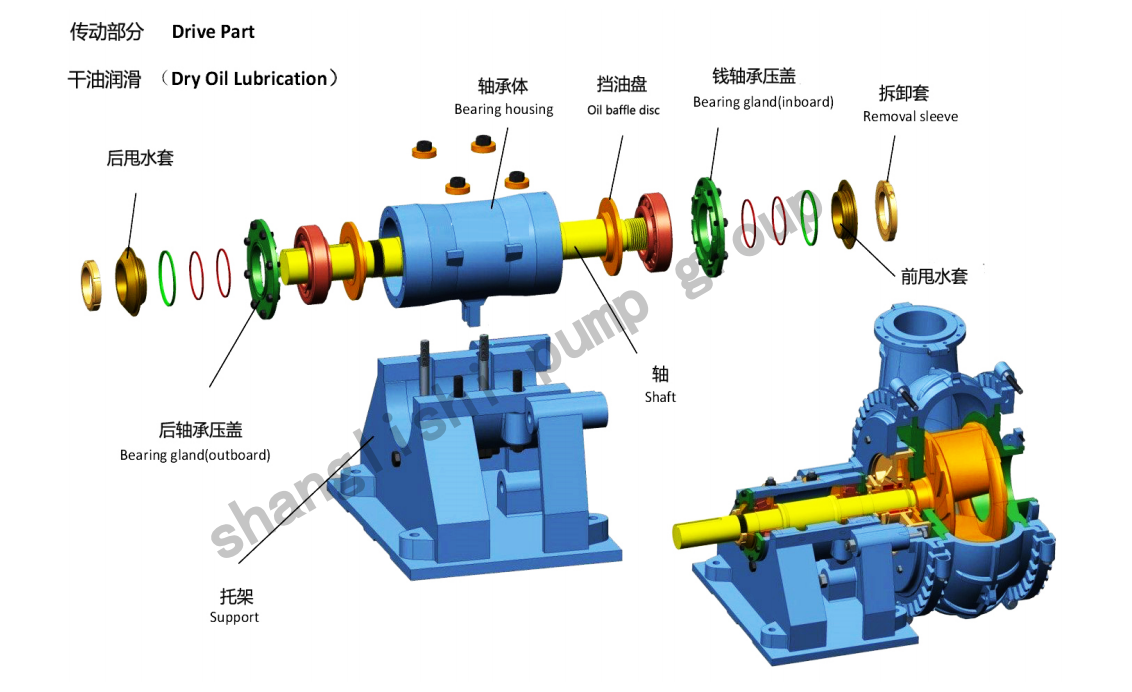

The gravel pump consists of a pump body, pump cover, and joint plate that are securely connected by a clamp band. This design allows for easy installation and maintenance. The discharge direction of the pump can be adjusted to any position within a 360-degree range, enhancing its usability in different settings. The pump is also equipped with a cylindrical bearing assembly that facilitates gap adjustments between the impeller and the pump body, allowing for straightforward maintenance.

Gravel Pump Performance Features

A gravel pump is a pump specially designed for conveying liquid media containing solid particles. Its product features mainly include:

Grease Lubrication: The lubrication system minimizes the risk of oil leakage and reduces maintenance efforts.

Wide Flow Channel: The design ensures good cavitation performance, high efficiency, and abrasion resistance.1. Strong wear resistance: The flow parts of the gravel pump are usually made of wear-resistant materials, which can effectively resist the wear of solid particles.

Efficient conveying capacity: The design can handle high concentrations of solid particles, ensuring efficient conveying efficiency.

Simple structure and convenient maintenance: The structure design of the gravel pump is simple, which is convenient for daily maintenance and repair.

Strong adaptability: It is suitable for a variety of working conditions, including but not limited to mining, construction, water conservancy and other fields.

Corrosion resistance: The flow parts can select suitable corrosion-resistant materials according to the characteristics of the conveying medium.

Adjustable flow and head: By changing the size or speed of the impeller, the flow and head of the pump can be adjusted to meet different working requirements.

Strong self-priming ability: Some gravel pumps have good self-priming ability and can be started without additional water suction devices.

Low energy consumption: Optimized hydraulic design and efficient drive system make the gravel pump have lower energy consumption during operation.Gravel Pump Drive Mechanisms

The gravel pump supports multiple drive options to suit various operational needs:

- V-shaped V-belt drive

- Elastic coupling drive

- Gear reducer drive

- Hydraulic coupler drive

- Variable frequency drive

- SCR speed control

These options allow the pump to operate under optimal conditions, enhancing its service life and efficiency.

SG Series Gravel Pump Application

The gravel pump is particularly effective in environments requiring the transportation of large particles, making it ideal for:

- River sand mining

- Mining vessels

- Dredging operations

Its ability to adapt to different speeds and configurations ensures it meets the demands of various transportation conditions while maintaining high operational efficiency.

Shanglishi Gravel pump stands out due to its robust design, effective lubrication system, versatile drive options, and suitability for challenging applications. Its innovative features make it an essential tool in industries dealing with abrasive materials.

The difference between SG series sand and gravel pump and standard slurry pump:

Feature SG Series Gravel Pump Standard Slurry Pump Abrasive Material Handling Handles large solid particles Limited particle size Efficiency High Moderate Maintenance Easy with adjustable components Frequent maintenance required Durability High-wear-resistant materials Standard materials Working conditions

Flow range: 36-4320m ³/h

Head range: 5-80m

Power: 60-1200kw

Speed: 720,990,1480 and 2960r/min

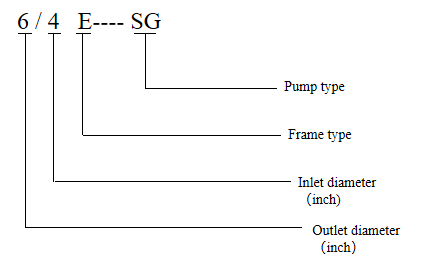

Main model: 6/4 8/6 10/8 12/10 14/12 16/14 18/16 20/18

Bracket form: B C D E F G ST

Medium: the particles are too large to the general slurry pump can not transport strong abrasive materials

Material classification: high chromium alloy

Model meaning

Performance parameters (for preliminary selection only)

Model

TYPE

Flow

CAPACITY

(L/S)

lift

HEAD

(M)

Speed

SPEED

(R/MIN)

Efficiency

EFFICIENCY

(%)

NPSH

NPSHr

(M)

Inlet diameter

INLET DIAMETER

(MM)

Outlet diameter

OUTLET DIAMETER

(MM)

Maximum flow particle size

MAX DIAMETER OF

FLOWED PARTICE

(MM)

6/4D-SG 10-70 3.5-51 600-1400 30-50 2.5-3.5 150 100 82 8/6E-SG 38-160 10-48 800-1400 50-60 3-4.5 200 150 127 10/8S-SG 60-272 13-50 500-1000 45-65 3-7.5 250 200 178 10/8F-SG 60-272 13-50 500-1000 45-65 3-7.5 250 200 178 12/10F-SG 100-420 11-58 400-850 50-70 2-4.5 300 250 220 12/10G-SG 100-420 11-58 400-850 50-70 2-4.5 300 250 220 14/12G-SG 140-880 6-66 300-700 60-68

2-8 350 300 241 18/16G-SG 240-1060 9-48 250-500 60-72 3-6 450 400 254 18/16T-G 240-1060 9-48 250-500 60-72 3-6 450 400 254 10/8S-SGH 110-360 18-80 500-950 60-72 2-5 250 200 180 12/10T-SGH 170-620 28-78 350-700 60-72 2-8 300 250 210 16/14TU-GH 200-1000 20-72 300-500 60-72 3-6 400 350 230 Product Structure

The picture on the left shows the structure of the gravel pump

The picture on the right is a schematic diagram of the integrated structure of gravel pump and pump box

breakdown structure

Transmission part

Sealing mode

The shaft seal of gravel pump has packing seal and vice impeller seal.

1. Packing seal: used for suction or backflow state. Shaft seal water pressure should be higher than the pump outlet pressure 35Kpa, shaft seal water see below.

2. Vice impeller seal: generally used for backward irrigation state. The backward water head does not exceed 10% of the total water head of the pump, and the shaft power will increase by about 5%.

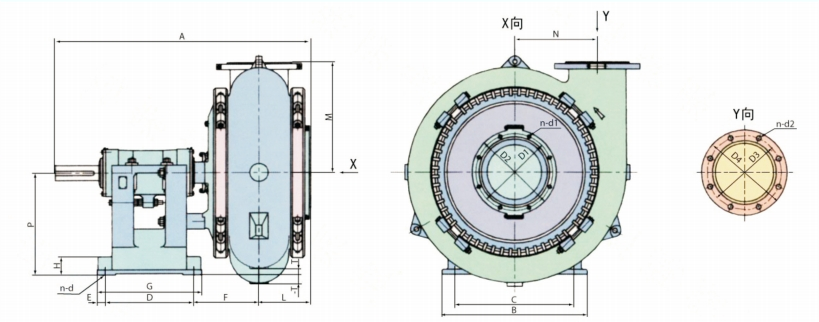

Exterior and installation dimensions of SG and SGH pumps

Pump model Overall dimension anchor hole Suction flange Spit outlet flange Weight

KG

A B C D E F G H L M N P T N-d D1 D2 n-d1 D3 D4 n-d2 6/4D-SG 1006 492 432 213 38 330 289 54 203 343 260 330 16 4-Φ22 260 305 8-Φ19 210 254 4-Φ19 460 8/6E-SG 1286 622 546 257 54 392 365 75 295 405 352 457 54 4-Φ29 324 368 8-Φ19 260 305 8-Φ19 1120 10/8F-SG 1591 857 762 349 45 487 540 98 330 533 416 610 60 4-Φ35 406 457 8-Φ22 324 368 8-Φ19 2250 12/10F-SG 1702 883 762 584 60 411 705 98 368 667 522 610 / 4-Φ35 470 527 12-Φ22 406 457 8-Φ22 3320 10/8S-SG 1720 920 760 640 70 378 780 90 330 533 416 450 / 4-Φ35 406 457 8-Φ22 324 368 8-Φ19 2285 12/10G-SG 2010 1207 851 749 64 473 876 152 368 665 522 851 238 4-Φ41 470 527 12-Φ22 406 457 8-Φ22 4450 14/12G-SG 2096 1207 851 749 64 502 876 152 424 787 610 851 121 4-Φ41 495 552 8-Φ19 470 527 12-Φ22 5400 18/16G-SG 2111 1207 851 749 64 503 876 152 432 914 692 851 / 4-Φ41 641 705 16-Φ28 584 641 2-Φ28 6950 18/16T-SG 2607 1397 1194 921 102 703 1124 222 432 914 692 1067 143 4-Φ67 641 705 16-Φ28 584 641 2-Φ28 8850 10/8S-SGH 1774 920 760 640 70 455 780 90 330 620 473 450 / 4-Φ35 406 457 8-Φ22 324 641 8-Φ19 3188 16/14TU-SGH 2375 1480 1200 860 95 649 1050 150 448 1010 765 900 / 4-Φ79 600 650 2-Φ28 540 600 12-Φ28 2250 Industry Applications

power system gravel pump

chemical industry gravel pump

metallurgical industry gravel pump

coal, mining industry gravel pump

river dredging gravel pump, river sand mining gravel pump and sand mining vessels gravel pump

municipal engineering gravel pump

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including: china Huadian, China Datang Group, Datang International, China Huaneng, China SDIC, China Guodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel Group, Yanshan Iron and Steel, etc.

The use of gravel pump in power system

The use of gravel pump in dredging river, river sand mining, sand mining ship

Use of gravel pump in coal and mine

The Use of Gravel Pump in Metallurgical Industry

The use of gravel pump in chemical industry

Application of Gravel Pump in Municipal Engineering

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP