PRODUCTS

CONTACT US

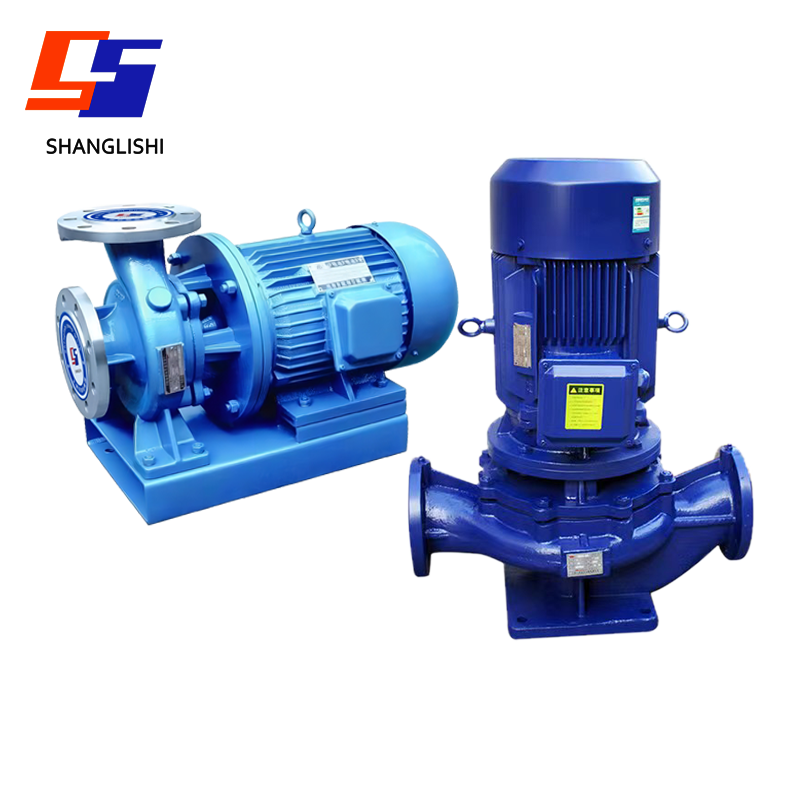

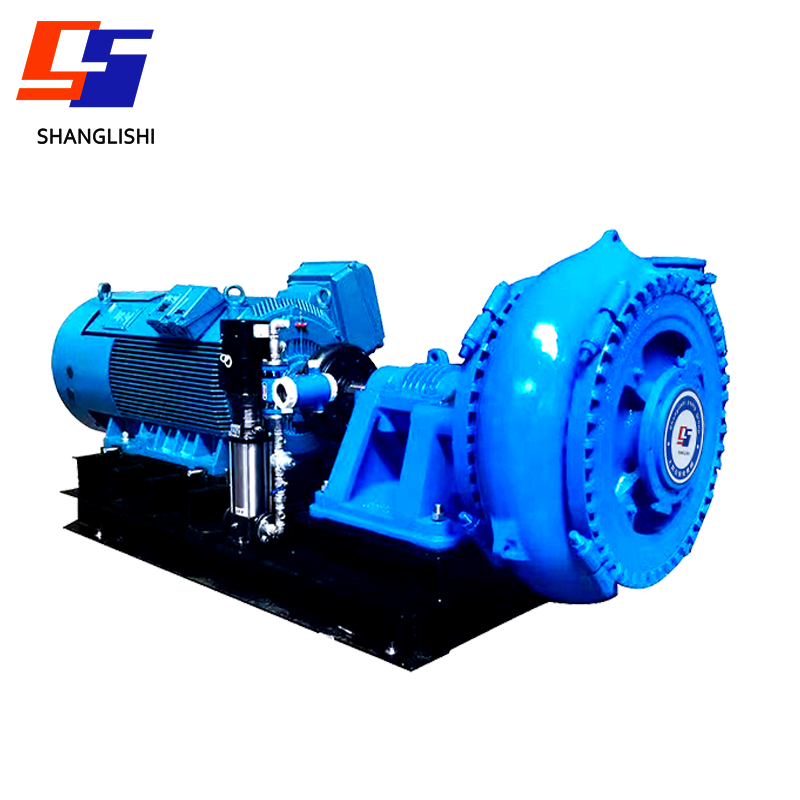

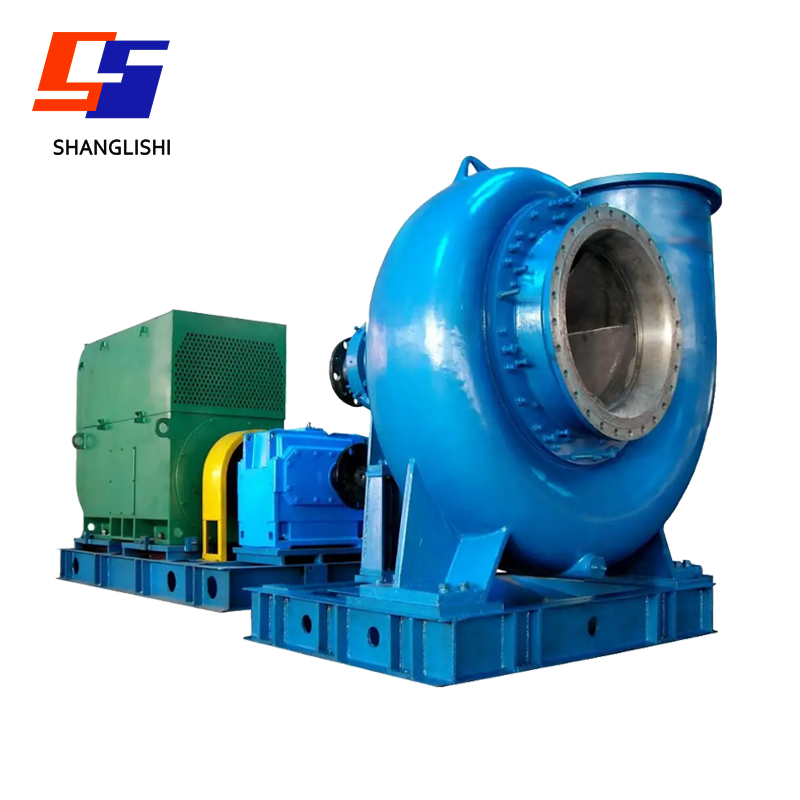

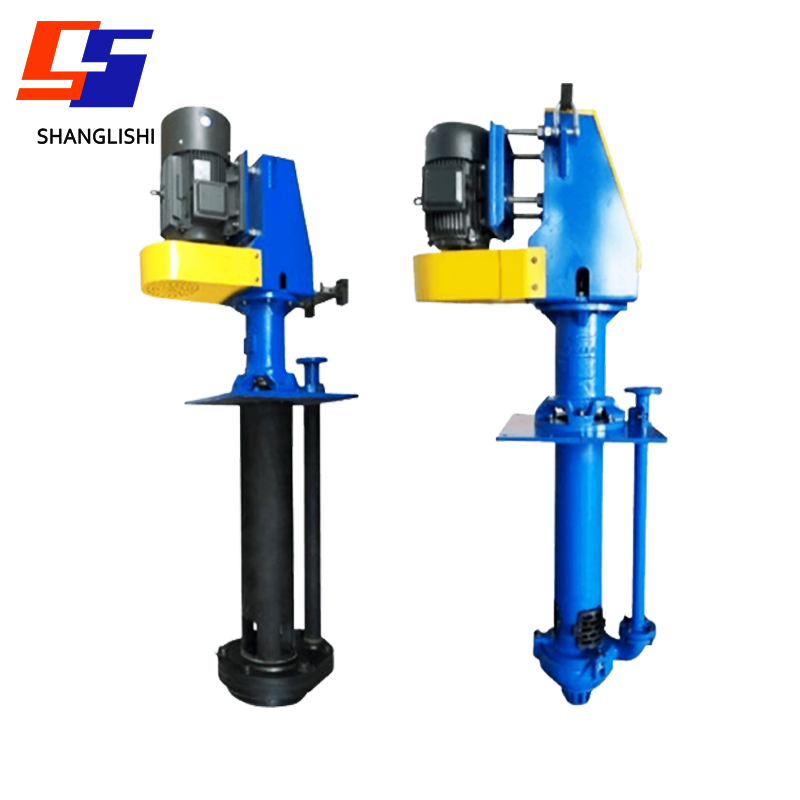

Vertical Centrifugal Pump Introduction

Shanglishi vertical centrifugal pump is an industrial pump commonly used for liquid transportation. It is widely used in water treatment, chemical, petroleum, pharmaceutical, food processing and other industries due to its advantages such as small footprint, high efficiency and stable operation. Vertical centrifugal pump drives the impeller to rotate through the motor, converting mechanical energy into liquid kinetic energy and pressure energy to achieve liquid lifting and transportation.

Features of Vertical Centrifugal Pump

Structure Design and Space Utilization

Compact Vertical Design: The Vertical Centrifugal Pump features a vertical design where the pump body and motor are coaxial, with the pump shaft oriented vertically, saving floor space. This is especially advantageous in confined installation spaces, such as underground pump rooms and compact industrial environments.

Modular Structure: The pump’s modular design makes it easy to replace or maintain individual parts. Both the pump body and impeller can generally be dismantled independently, minimizing downtime during maintenance.

High-Performance Fluid Dynamics

Optimized Impeller Design: The impeller, a key component of the Vertical Centrifugal Pump, is typically streamlined with either a closed or semi-open design to reduce fluid loss. Its geometry is optimized through CFD (Computational Fluid Dynamics) analysis, significantly improving both flow rate and head while reducing energy consumption.

Multistage Pump Design: Many Vertical Centrifugal Pumps feature a multistage impeller setup, where each stage adds incremental head pressure. This design is ideal for high-head applications such as deep-well pumping or water supply for high-rise buildings.

Material Selection and Corrosion Resistance

Corrosion-Resistant Materials: The pump body and impeller materials are available in stainless steel, cast iron, carbon steel, or corrosion-resistant alloys, catering to various corrosive liquids. For fluids containing solids or abrasive particles, wear-resistant materials such as nickel-chrome alloy or ceramic-coated materials can be used to extend the pump’s service life.

High-Precision Sealing Components: The Vertical Centrifugal Pump employs mechanical or double-face seals to prevent leaks and resist corrosion, making it suitable for handling corrosive media in chemical industries. This design enhances both pump body and seal durability.

Stability and Low Noise

Robust Bearings and Damping Design: Heavy-duty bearings enable the Vertical Centrifugal Pump to handle high loads while minimizing vibration. Rubber damping pads or flexible couplings are typically incorporated, effectively reducing transmitted vibration and noise, ideal for noise-sensitive applications such as water treatment systems in residential or commercial buildings.

Balanced Pressure Design: Impeller pressure-balancing techniques help avoid axial thrust issues, extending bearing life and reducing wear and noise from uneven pressure distribution.

Ease of Maintenance and Operational Efficiency

Split Maintenance Structure: The pump’s split maintenance structure allows for easy disassembly, enabling access to and replacement of critical components like the impeller and shaft seal by simply removing the upper cover. This structure eliminates the need to detach piping, improving service efficiency.

Automated Control and Monitoring: Compatible with remote monitoring systems, the Vertical Centrifugal Pump can monitor key parameters such as flow, pressure, and temperature via sensors, enabling automatic start, stop, and flow regulation to reduce manual intervention and support intelligent management.

Application Adaptability and Energy-Saving Design

Variable Frequency Drive Compatibility: The Vertical Centrifugal Pump supports VFD control, allowing speed adjustments to match system pressure requirements, saving energy. VFD control is particularly efficient in water supply systems with fluctuating demand, making it ideal for precise flow control in industrial applications.

Broad Application Suitability: The Vertical Centrifugal Pump is suitable for diverse applications, including building water supply, wastewater treatment, chemical fluid handling, and agricultural irrigation. It performs especially well with clean water, acidic or alkaline chemical solutions, light-duty wastewater, and oils.

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP