The difference between pipeline pump and centrifugal pump

Published:

Sep 05,2024

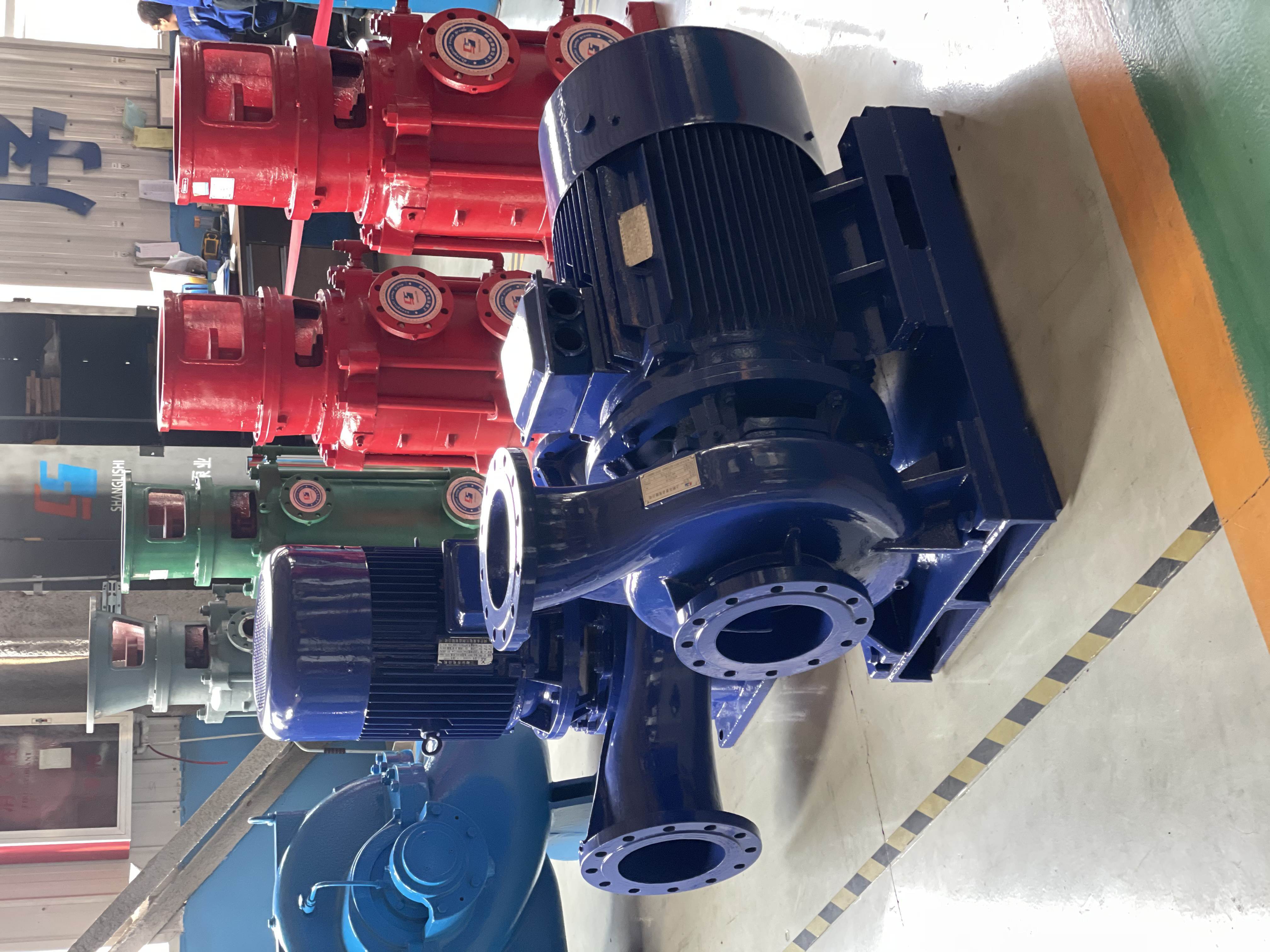

Centrifugal pumps and pipeline pumps are two different types of pumps commonly used in industrial production. They have some obvious differences in structure, working principle and application occasions.

1. Structural differences

Centrifugal pumps are mainly composed of impellers, pump casings, shaft seals and other parts. The impeller is the core component of the centrifugal pump. It generates centrifugal force through rotation to throw the liquid out of the center of the impeller and flow out through the pump casing. The pipeline pump is mainly composed of inlet and outlet pipes, pump casings, impellers and other parts. The inlet and outlet pipes are components that connect the pump and the pipeline and play a role in guiding the water flow.

2. Different working principles

The working principle of the centrifugal pump is to use the centrifugal force generated by the rotation of the impeller to throw the liquid out of the center of the impeller and flow through the pump casing to the outlet pipe. During the rotation of the impeller, the energy generated when the liquid is thrown out will cause the liquid to flow faster, thereby forming a certain pressure and flow rate. The working principle of the pipeline pump is to introduce the liquid into the pump casing through the inlet and outlet pipes, and then generate energy through the rotation of the impeller to make the liquid flow out of the outlet pipe.

3. Different use occasions

Centrifugal pumps are mainly used to transport liquids, such as water, oil, acid and alkali liquids, etc., and are suitable for liquid transportation and circulation in various industrial production processes. Pipeline pumps are mainly used to transport liquids from pipelines to other equipment or systems, such as material transportation in chemical production, water circulation in water treatment, etc.

4. Different performance parameters

The flow rate and head of a centrifugal pump are its main performance parameters. The flow rate refers to the amount of liquid passing through the pump per unit time, and the head refers to the pressure difference that the pump can generate. The performance parameters of pipeline pumps mainly include flow rate, head, power, etc., among which the flow rate and head are similar to those of centrifugal pumps, but the power of pipeline pumps is usually smaller because its main function is to transport liquids from pipelines to other equipment or systems.

5. Different selection basis

In industrial production, the selection of suitable centrifugal pumps or pipeline pumps needs to be selected according to actual needs. For the selection of centrifugal pumps, it is necessary to consider parameters such as the properties of the liquid, flow rate and head, as well as factors such as the efficiency and reliability of the pump. When selecting a pipeline pump, you need to consider the size of the inlet and outlet pipelines, the properties of the liquid, the flow rate and head, as well as the installation and use environment of the pump.

In short, centrifugal pumps and pipeline pumps are two different types of pumps, which have obvious differences in structure, working principle and application occasions. In industrial production, it is necessary to select the appropriate pump type according to actual needs and carry out corresponding selection work.

Keyword:

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15203151828

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP