Main factors of wear of slurry pump flow parts

Published:

Dec 30,2024

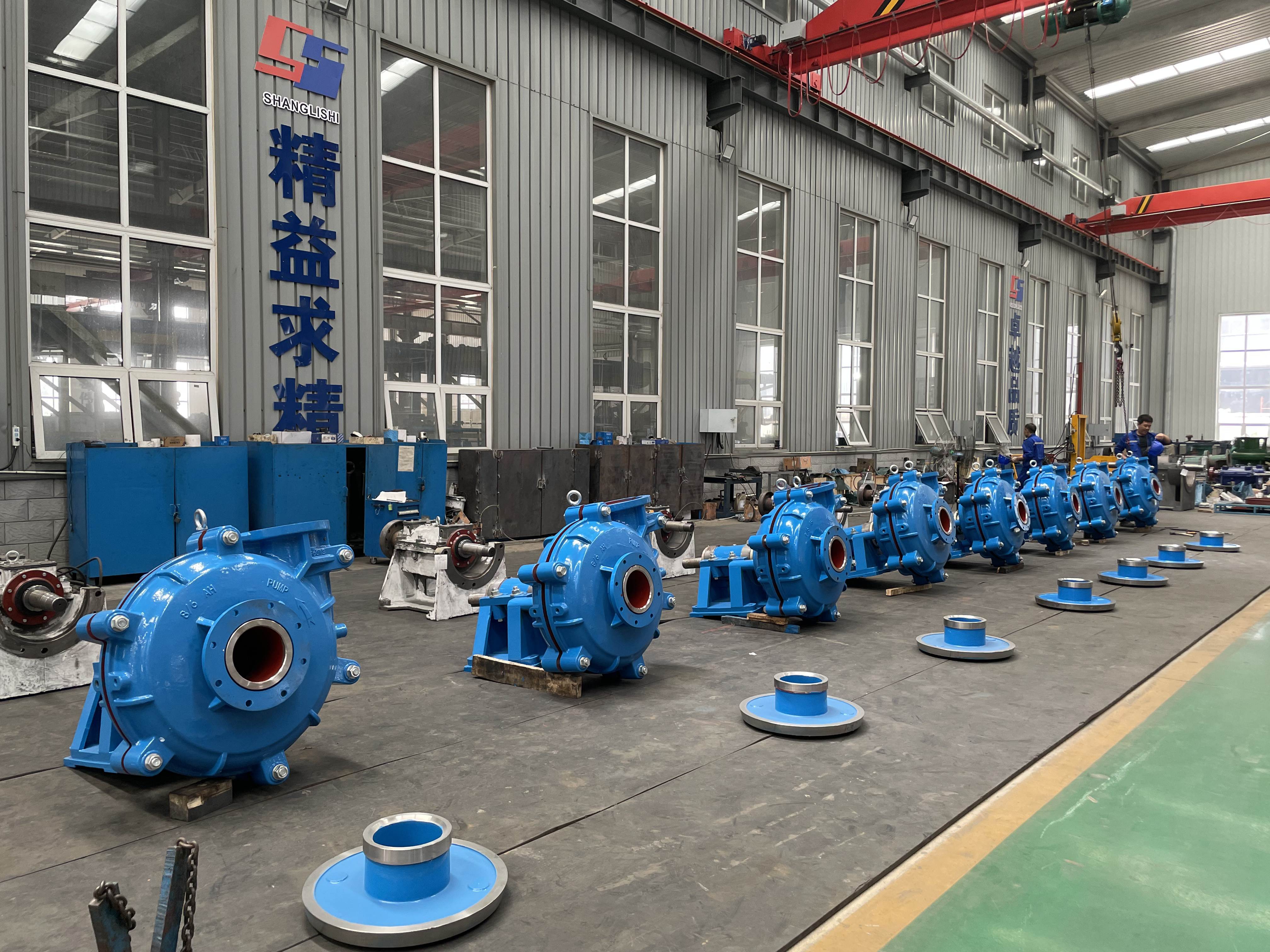

The flow components of a slurry pump refer to the parts that come into direct contact with the conveyed medium, mainly including the impeller, volute, front guard plate, and rear guard plate. These components endure high-speed scouring and wear from the medium during the operation of the slurry pump. This article briefly introduces the reasons for the wear of slurry pump flow components.

Main factors affecting the wear of slurry pump flow components:

1. Concentration and flow rate of the slurry

Under the same operating conditions, as the concentration of the slurry decreases, meaning the solid particle content in the slurry decreases, the scouring effect of solid particles weakens, and the service life of the slurry pump flow components increases.

As the flow rate of the slurry increases, the number of impacts of solid particles on the material surface per unit time increases, leading to an increase in material loss. Therefore, an increase in the flow rate of the slurry will accelerate the wear of the flow components, reducing their service life.

2. pH of the slurry

Additionally, particle size, hardness, and the impact angle of particles on the material surface also have a significant effect on material erosion wear.

In addition to the aforementioned slurry factors, design factors of the slurry pump, the properties of the materials themselves, and the hardness of the materials will also have an impact.

Keyword:

Slurry pump,The use of slurry pumps

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP