SCZ chemical pump

Keyword:

Classification:

- Description

- Main Projects

- Product Video

-

ProductsOverview

- SCZ series standard chemical pump is a horizontal single stage single suction cantilever centrifugal pump. The performance range of this series of chemical pumps includes all the performance of IH series standard chemical pumps. Its efficiency, cavitation performance and other indicators exceed IH type pumps, and can be interchanged with IH type pumps.

-

SCZ type chemical pump can transport low or high temperature liquid, neutral or corrosive liquid, clean or liquid containing solid particles. It can be widely used in chemical industry, fertilizer, metallurgy, electric power, papermaking, food, pharmaceutical, synthetic fiber and other industries. Especially suitable for: chemical and petrochemical industries, oil refineries, paper mills, pulp and coating industries.

Working conditions

Flow rate: up to 2000 m/h

Head: up to 160m

Working pressure: 2.5MPa

Working temperature:-80 ℃ ~ 300 ℃

Medium: various temperatures and concentrations of sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid and other inorganic and organic acids.

Alkaline concentrates such as sodium hydroxide and sodium carbonate at various temperatures and concentrations.

Coating industry degreasing, phosphating, electrophoresis and other processes.

Various liquid petrochemicals, organic compounds and other corrosive raw materials and products.

At present, the corrosion-resistant materials of our factory can meet the requirements of various media mentioned above. When ordering, please provide the user with the details of the medium to be transported.

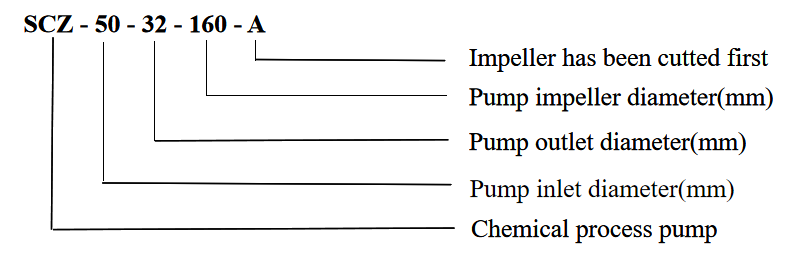

Model meaning

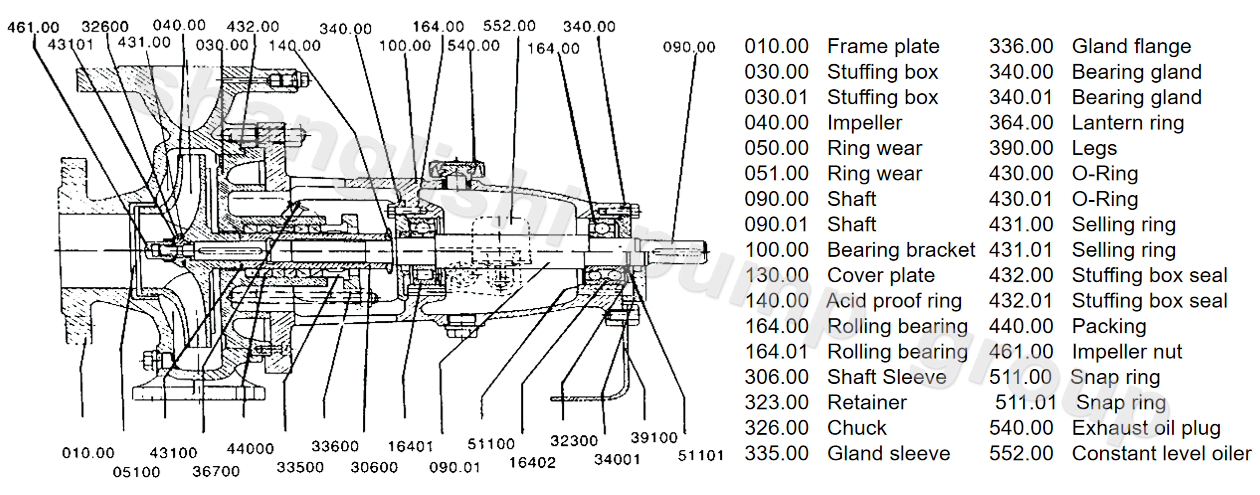

Product Structure

Product Structure

Product Features

Product Features

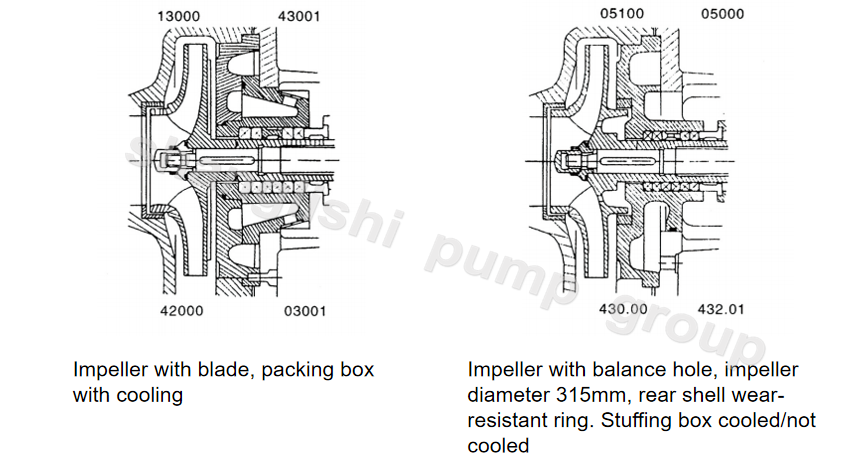

- The pressure acting on the shaft seal is balanced by the balance hole on the blade or impeller. The shaft seal can use soft packing seal (can be cooled, also can not be cooled), can also use a variety of structures of single, double mechanical seal (can use a variety of structures of single, double mechanical seal (can be balanced).

- The ball bearing is durable and the shaft diameter is abundant to ensure smooth operation.

- Part of the specifications of the pump body is designed as a double screw housing to balance the radial force. The bearing frame, including the shaft, impeller, stuffing box, etc., forms a combined part, so that the pump body does not need to be removed from the pipeline during maintenance (if the extension coupling is used, the motor does not need to be removed). Flange design, using PN16, PN25 two (based on material differences).

- Horizontal rear door structure, the pump head and the motor are connected by a coupling, installed on the bottom plate, the impeller is rear-open, three bearings, the shaft seal adopts an external mechanical seal, with a cooling device, and the oil level of the bearing body is used Oil mirror observation; compact and reasonable structure.

- The pump has a foot on the pump body, which can bear the load from the pipeline and directly transmit it to the foundation, so that the pump rotor will not bend due to the load on the pump, thus ensuring the best service life of the bearing and mechanical seal.

- Maintenance does not need to open the pipeline connected to the pump body, as long as the opening of the bracket and the bolt of the pump body, the two can be separated from the maintenance of the impeller and mechanical seal, simple and convenient.

- The import and export of the pump are on the same axis, which is convenient for design and process to take over.

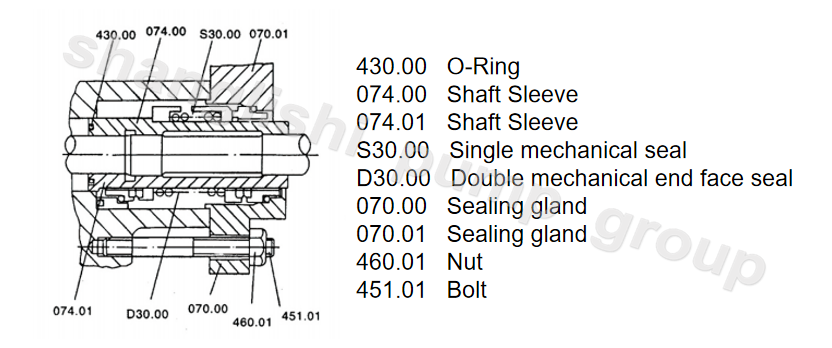

Partial view of mechanical seal

Industry Applications

Industry Applications

Particularly suitable for the chemical and petrochemical industries

Especially suitable for oil refineries

Especially suitable for paper mills, pulp industry and coating industry

Widely used in chemical, fertilizer, petroleum and other industries

Suitable for food, pharmaceutical and synthetic fiber industries

Suitable for metallurgy, electric power and other industries

-

Our products are widely used in metallurgy, mining, electric power, coal, petroleum, chemical, environmental protection, building materials, municipal and other industries, long-term service in the domestic well-known high-end customer base, including:ChinaHuadian,ChinaDatang Group, Datang International,ChinaHuaneng,ChinaState Investment,ChinaGuodian, Hebei Iron and Steel Group, Shandong Iron and Steel Group Rizhao Iron and Steel, Kunming Iron and Steel, Baotou Iron and Steel, Benxi Iron and Steel Group, Tianjin Iron and Steel Group, Jiuquan Iron and Steel, Kunming Iron and Steel, Handan Iron and Steel, Hebei Xuangang, Anyang Iron and Steel, Tangshan Iron and Steel Group, Donghai Iron and Steel, Yanshan Iron and Steel, Jiujiang Wire, Jiujiang Pinggang, Donghai Special Steel, etc.

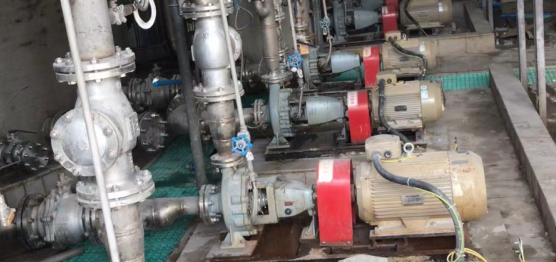

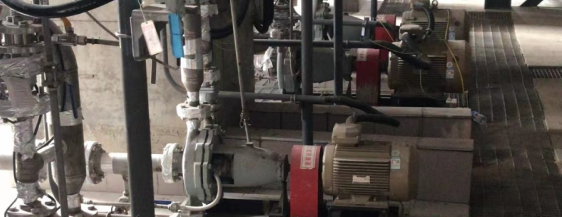

Application of Chemical Pump in Petrochemical Industry

Application of chemical pump in petroleum industry

Application of Chemical Pump in Synthetic Fiber Industry

Application of Chemical Pump in Electric Power Industry

Application of Chemical Pump in Electric Power and Metallurgical Industry

Application of chemical pump in food and pharmaceutical industry

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15203151828

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP