The Essential Guide to Gravel Pumps: Applications, Advantages, and Maintenance

Published:

Feb 14,2025

Gravel pumps may not be the most glamorous pieces of equipment, but they are integral to various industries, particularly those that involve handling abrasive materials such as gravel, sand, and slurry.

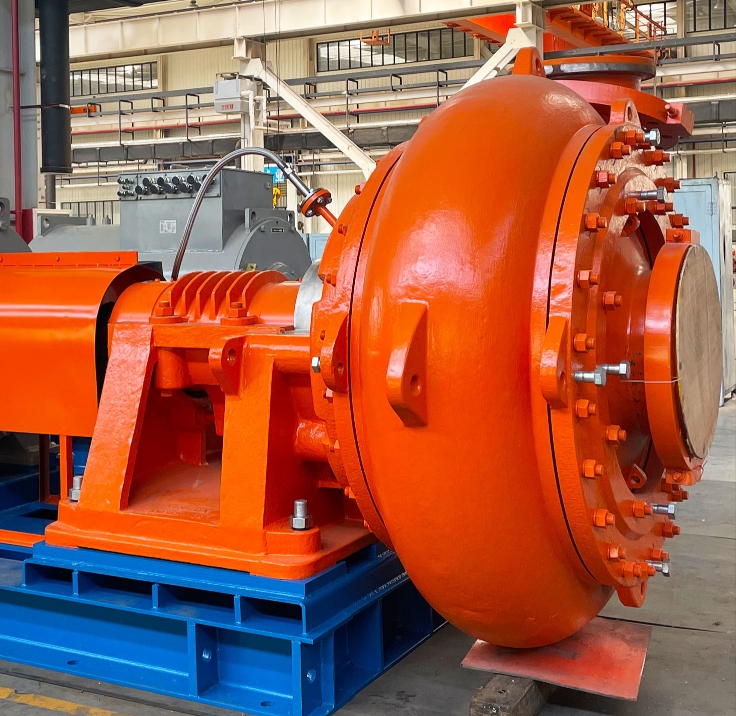

Gravel pumps may not be the most glamorous pieces of equipment, but they are integral to various industries, particularly those that involve handling abrasive materials such as gravel, sand, and slurry. These pumps are robust, purpose-built machines designed to efficiently move these challenging materials in applications ranging from mining to construction and dredging. In this comprehensive guide, we will explore what gravel pumps are, their working principles, different types, applications, advantages, and essential maintenance tips. Whether you are a professional in the field or simply curious about the function of this specialized equipment, this article will provide you with a deeper understanding of gravel pumps.

What is a Gravel Pump?

A gravel pump is a type of centrifugal pump specifically designed to transport abrasive materials like gravel, sand, and slurry. These pumps are a critical part of various industrial operations that require the efficient and reliable movement of these heavy and often coarse materials. Gravel pumps are typically centrifugal in design, meaning they use a rotating impeller to generate centrifugal force, which propels the material through the system.

Gravel pumps are essential in industries where the efficient transfer of high-solid-content fluids is needed. These machines are built to withstand harsh conditions, including abrasive particles, large solid particles, and even corrosive environments, making them vital for mining, dredging, and construction industries.

Key Components of a Gravel Pump

Understanding the primary components of a gravel pump can help explain how it functions and why it’s effective at handling abrasive materials. Here are the key components:

Impeller: The impeller is a rotating part of the pump that creates centrifugal force. It pushes the material through the pump casing by imparting kinetic energy, thereby accelerating it.

Casing: The casing is the outer housing that surrounds the impeller. Its main job is to direct the flow of material from the inlet to the discharge port. The casing often features a wear-resistant lining to prevent excessive damage from abrasive particles.

Suction Pipe: The suction pipe connects to the pump inlet and is responsible for drawing in the material to be pumped. Often, it includes a strainer or mesh to prevent large debris from damaging the pump.

Discharge Pipe: The discharge pipe carries the material from the pump to the desired location. It may include valves or fittings to control the flow and direction of the material.

Motor or Diesel Engine: The motor or power source drives the pump. Depending on the application, gravel pumps can be powered by electric motors or diesel engines.

How Does a Gravel Pump Work?

The working process of a gravel pump can be broken down into several key stages:

Priming: Before the pump is started, both the suction pipe and casing need to be filled with fluid to create a vacuum. This process is essential to ensure the pump can effectively draw in material.

Material Intake: Once the pump is primed, the rotating impeller generates centrifugal force. This force draws the material into the pump through the suction pipe.

Centrifugal Action: Inside the pump casing, the high-speed impeller rotates, causing the material to move in a circular motion. The centrifugal force generated pushes the material toward the pump’s casing walls.

Pressure Generation: The material is forced out through the discharge pipe as pressure builds within the casing due to centrifugal force.

Material Transport: Finally, the material is transported to the designated location via the discharge pipe. The velocity and pressure created by the impeller ensure the material moves efficiently over long distances.

Different Types of Gravel Pumps

Several types of gravel pumps are designed to cater to different operational needs. The most common types include:

Horizontal Centrifugal Gravel Pump: The most common type of gravel pump, it features a horizontal shaft with an impeller that rotates within a horizontal casing. These pumps are widely used in mining, construction, and dredging.

Vertical Centrifugal Gravel Pump: These pumps have a vertical shaft and are typically used in applications where the pump needs to be submerged in the liquid. They are ideal for underwater dredging and sump pumping.

Submersible Gravel Pump: Fully submersible, these pumps operate underwater and are used in dredging and mining operations in deep waters or limited-access environments.

Dredge Pump: Dredge pumps are specifically designed for the dredging industry, where they are used to remove sediment and materials like sand from the bottom of bodies of water. These pumps are built to handle large volumes of slurry with high solid content.

Slurry Pump: While not exclusively for gravel, slurry pumps are effective at transporting abrasive mixtures of solids and liquids. They are used in applications involving mineral processing, coal washing, and other industries where high-solid content slurries need to be handled.

Applications of Gravel Pumps

Gravel pumps are used across various industries where abrasive materials need to be moved efficiently. Some of the key applications include:

Mining: In mining operations, gravel pumps are used to transport slurry containing minerals like gold, diamonds, or tin. Alluvial mining, in particular, uses gravel pumps to process gravel and sand deposits to extract valuable minerals.

Dredging: Dredging operations, which involve removing sediment and debris from the beds of water bodies, rely on gravel pumps to transport sand, silt, and other materials. These pumps play a vital role in maintaining navigational channels and performing land reclamation.

Construction: Gravel pumps are used on construction sites to move sand and gravel for foundation building, land reclamation, and aggregate supply. They allow for easy transportation of materials across large or challenging construction sites.

Sand and Gravel Industry: Gravel pumps are indispensable in the sand and gravel extraction industry, allowing for the efficient transport of these materials from rivers, quarries, and mining sites.

Industrial Processing: Many industries like coal washing, chemical processing, and power generation use gravel pumps to transport abrasive slurries containing minerals, coal, and chemicals.

Environmental Cleanup: Gravel pumps are also used in environmental cleanup operations to remove debris and pollutants from bodies of water, helping restore the ecological balance of aquatic environments.

Advantages of Gravel Pumps

Gravel pumps offer numerous benefits, making them the preferred choice for handling abrasive materials:

Efficient Handling of Abrasive Materials: Designed with durable components, gravel pumps can withstand the wear and tear caused by abrasive materials, ensuring reliable and efficient material handling over time.

High Solids Handling Capacity: Gravel pumps can handle materials with a high concentration of solids, such as sand, gravel, and slurry, making them ideal for mining, dredging, and slurry transportation.

Versatility: Gravel pumps are versatile and can be used in a wide range of applications, from mining to construction and environmental cleanup.

Cost-Effective Operation: With their ability to handle tough materials efficiently, gravel pumps reduce the need for frequent repairs and replacements, offering a cost-effective solution for industries with high abrasive content.

Easy Maintenance: Gravel pumps are designed for ease of maintenance, with accessible components that can be inspected, repaired, or replaced quickly, reducing downtime and operational costs.

Factors to Consider When Choosing a Gravel Pump

When selecting a gravel pump for your application, several factors should be considered:

Particle Size: The size and abrasiveness of the particles being pumped will determine the type of pump required. Larger particles may require specialized pumps with wear-resistant components.

Flow Rate and Head: Ensure that the pump can meet the required flow rate and head pressure for your specific operation.

Pump Construction: Consider the materials used in the pump’s construction. For abrasive applications, wear-resistant materials are essential to ensure longevity and efficiency.

Power Source: Depending on the availability of power, you may choose between electric, diesel, or hydraulic-powered pumps.

Proper Operation and Maintenance of Gravel Pumps

To ensure a gravel pump operates efficiently and lasts longer, it’s essential to follow best practices for operation and maintenance:

Regular Inspections: Check for wear and tear, corrosion, and potential blockages regularly.

Lubrication: Ensure the pump’s moving parts are well-lubricated to prevent overheating and excessive friction.

Cleanliness: Regularly clean the pump and flush out any debris to prevent clogging.

Proper Installation: Follow the manufacturer’s guidelines for correct installation to avoid operational issues and excessive wear.

Conclusion

Gravel pumps are vital pieces of equipment that play an essential role in various industries, from mining to construction and dredging. Their robust construction, high solids handling capacity, and versatile applications make them indispensable for efficiently transporting abrasive materials. By understanding the different types, advantages, and maintenance needs of gravel pumps, industries can optimize their use for improved productivity and efficiency. With proper operation and care, gravel pumps can deliver reliable performance for years, making them a crucial asset in handling challenging materials.

Keyword:

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86 15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP