SH/SCZ/SZA Series Chemical Pump

Keyword:

Classification:

- Description

- Application

- Main Projects

- Technical Drawing

- Product Video

-

Product Specification

Inlet diameter: 50-200mm

Capacity: 3-250m³/h

Head: 4-250m

Power: 0.55KW--160KW

Materials: Stainless steel SS304, SS316, polymer polyethylene.Product Description

★ SZA type series pumps are single-stage, horizontal, radial partial case pumps. It is suitable for conveying neutral or corrosive liquids, especially suitable for conveying liquid petrochemicals of various temperatures, acid and alkali solutions of various temperatures and concentrations and other corrosive liquids.

★The pump is suitable for petroleum refining, petrochemicals refining, chemical industry engineering, electric power engineering, environmental protection engineering, oil transmission engineering and paper making, pharmaceutical, sugar making and other industries.

★ SH/SCZ/SZA series chemical centrifugal pumps are products independently developed by our company.

★ Patent number: ZL202122043784.4, ZL202122901739.8

★ SH/SCZ/SZA Series chemical process pumps are designed and produced in accordance with API610 specifications. The SZA pump body is supported by feet. Single suction radial impeller, axial suction, radial discharge.

★ According to the conditions of use, use front and rear mouth rings and balance holes for hydraulic balance. The stuffing box has cooling or heating pipe connections. The shaft seal is sealed with stuffing, and single-end or double-end mechanical seals can also be used. And equipped with cooling, flushing or sealing liquid system.

Model Meaning

SZA 40-160

SZA ——Petrochemical process pump

40 ——Pump outlet diameter(mm)

160 —— Pump impeller diameter(mm)

Performance Range

Working pressure: 5.0 MPa

Working Temperature: -80℃ to +450℃

This series of pumps are single-stage, single-suction horizontal centrifugal pumps, and the impeller is a closed impeller.

It can transport liquid petrochemical products of various temperatures, acid, alkali and salt solutions of various temperatures and concentrations and other corrosive liquids.

Product Advantage

The SH/SCZ/SZA series chemical process pump adheres to standard API specifications for its design. There are three kinds of impellers: closed type, semi-open type and open type. It can transport clean, particle-containing, and a small amount of gaseous media. It can also transport high temperature, low temperature and strong corrosive media. The impeller is equipped with a balance hole and a corrosion-resistant ring to balance the axial force.

The pump body and bearing frame are connected via an intermediate section. According to different working conditions, different materials can be used for the intermediate connecting section to avoid severe corrosion of the bearing frame and bearing when transporting strong corrosive media. At the same time, the middle connecting section is provided with a water-cooling cavity, through which cooling circulating water is passed to block the high-temperature medium from transmitting high temperature to the bearing.

The sealing options include stuffing seals, single or double-end mechanical seals, and cartridge-type single-end mechanical seals. Users can select the appropriate seal based on their specific requirements and in accordance with API682 design specifications.

The bearing frame is available in three designs: air-cooled heat sink, air-cooled fan, and water-cooled cavity, providing users with choices based on their operational conditions. Bearings are lubricated using thin oil splashed from the tank by an oil ring. The oil in the tank is cooled by water in the water cooling chamber, ensuring the bearings remain in a normal working condition by dissipating heat with cold water.

Product Usage

It can transport inorganic acid and organic acid solutions such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations; alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations; various salt solutions; various liquid petrochemicals products, organic compounds, and other corrosive liquids. This type of pump is suitable for oil refinery, petrochemical industry coal processing engineering, low temperature engineering, paper industry, sugar industry, water supply plant, seawater desalination plant, power plant, environmental protection engineering and shipbuilding industry, etc. Viewed from the motor side, the pump rotates in a clockwise direction.

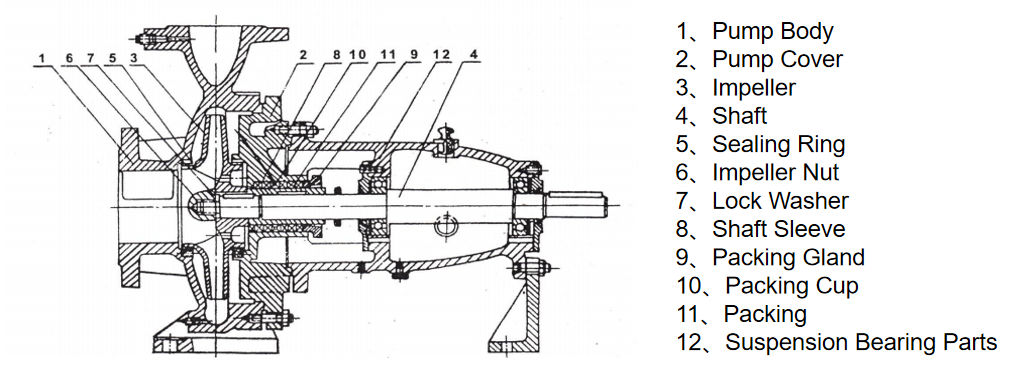

Structure Drawing

-

1. Chemical pumps (made of stainless steel) are widely used in petroleum, chemical industry, metallurgy, synthetic fiber, pharmaceutical, food, synthetic fiber and other departments to transport alkaline corrosive media;

2. Chemical pumps (made of fluorine plastic) are used to transport any acidic, alkaline corrosive media;

3. Chemical pumps (made of cast iron) are used for industrial and urban water supply and drainage. They can also be used for farmland and orchard drainage and irrigation to transport clean water or other liquids with physical and chemical properties similar to clean water.

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86-15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP