STL Series Desulfurization Pump(FGD Pump)

Keyword:

Classification:

- Description

- Application

- Main Projects

- Technical Drawing

- Product Video

-

Product Specification

Inlet/Outlet diameter: 25-900mm

Capacity: 600-25000m³/h

Head: 20~150m

Speed: 720,990,1480 and 2960r/min

Power: 300-5000kw

Materials: High chrome alloy.Product Description

★ The STLD series slurry pumps are divided into two categories. One is the TL type, which is a horizontal axial suction single-stage single-suction centrifugal slurry pump; the other is the TLL type, which is a vertical axial suction single-stage single-suction centrifugal slurry pump. Suction centrifugal slurry pump.

★ The STL series desulfurization pumps comprehensively apply and innovate the advantages of similar domestic and foreign products in terms of hydraulic design, structural design and wear-resistant materials. They have high efficiency, energy saving, low vibration, low noise, reliable operation, long service life, and easy maintenance. Characteristics, the comprehensive performance of the pump ranks at the leading domestic level, and the efficiency indicators of most pumps rank at the internationally advanced level.

★ It can be widely used in electric power, metallurgy, coal, building materials and other industries to transport slurry containing solid particles. Such as thermal power plant desulfurization, hydraulic ash removal, metallurgical dressing plant slurry transportation, coal washing plant coal slurry and heavy medium transportation, etc.

★ The maximum slurry weight concentration Cw allowed to be transported is: ash (slag) slurry and coal slurry 45%; ore slurry and heavy medium 60%.

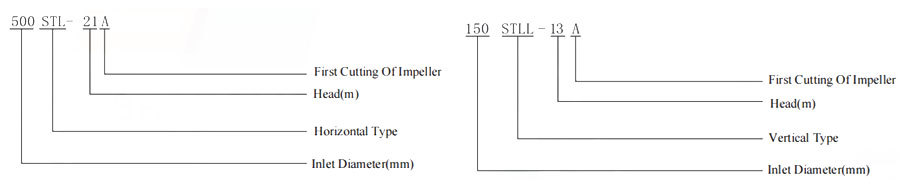

Model Meaning

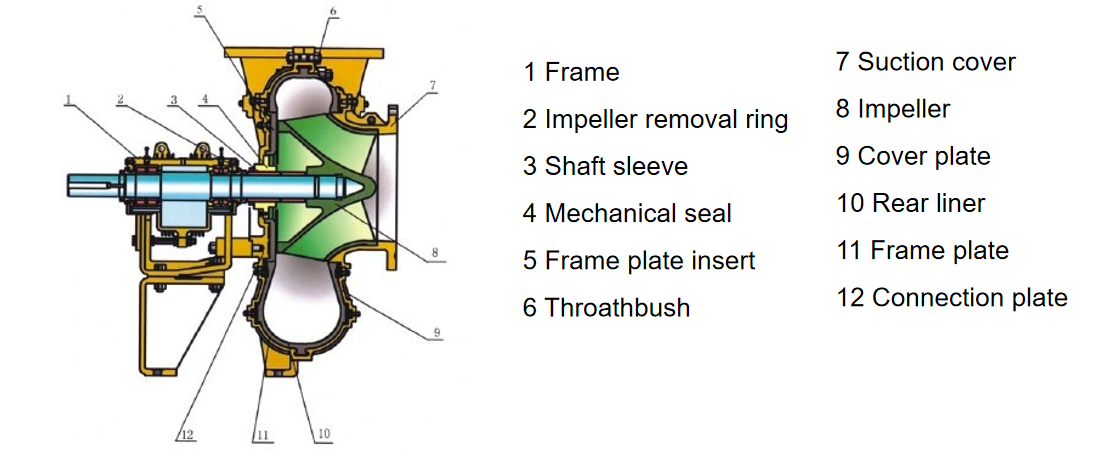

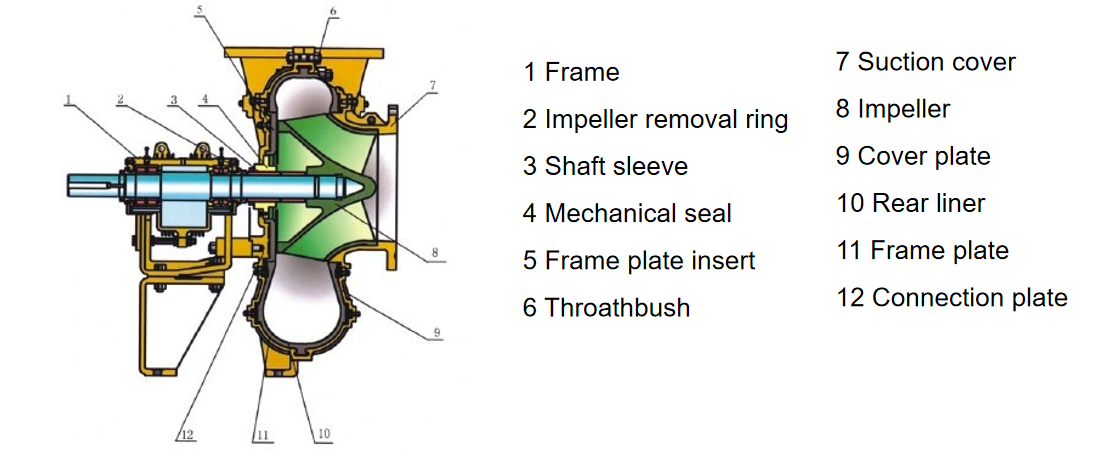

Struction Description

Structural characteristics of STL type slurry pump

Bare shaft part:

The pump head part of STL type slurry pump includes pump casing, impeller and shaft seal device. The pump head and bracket are connected with bolts. According to needs, the water outlet position of the pump can be rotated at eight different angles at 45° intervals for installation and use.

The pump casing of the STL type slurry pump has both a double-layer casing structure and a single-layer casing structure. The outer layer of the double-layer structure is a metal pump casing (front pump casing, rear pump casing), whose material is usually HT200 or QT500-7; the inner shell can be made of wear-resistant and corrosion-resistant high-chromium alloy cast iron (including the volute , front guard, rear guard), or made of rubber (including front volute and rear volute).

The impeller is composed of a front cover, a rear cover, blades, and back blades. The leaves are twisted leaves, usually 3-6 in number. The back blades are distributed on the outside of the front cover and rear cover, usually 8 in number. The impeller is made of high-chromium alloy cast iron, and the impeller and shaft are threaded.

The shaft seal device has three types: auxiliary impeller + packing combination seal, packing seal, and mechanical seal.

The auxiliary impeller + packing combination sealing type consists of a stuffing box, auxiliary impeller, water seal ring, packing, packing gland, and shaft sleeve.

The packing seal type consists of a stuffing box, a spacer sleeve, a water seal ring, a packing, a packing gland, and a shaft sleeve.

The mechanical seal type consists of stuffing box, spacer sleeve, mechanical seal, gland and shaft sleeve.

Bracket part:

The front pump casing is elevated and placed flat on the ground. The front guard plate is installed with stud bolts. Use a lifting tool to lift it into the front pump casing and fasten it with the front pump casing.

Install the front guard plate sealing ring and front pump casing lifting eye screws.

Lift the front pump casing and front fender, push the outer cone of the front fender into the cone hole of the volute, adjust the distance between the top surface of the volute outlet and the top surface of the front pump casing outlet to 5mm, and then tighten all the Pump body bolts.

Adjust the gap between the impeller and the front guard plate to 0.75-1.00mm. The adjustment method is the same as above.

Structure Diagram

-

The desulfurization pump is a pump with corrosion resistance and is mainly used for transporting corrosive liquids. It is a widely used pump among general equipment pumps.

1. Sulfate and phosphate fertilizer industry: transportation of dilute acid, mother liquor, sewage, sea water, fluorosilicic acid containing silica gel, phosphoric acid slurry and other media.

2. Non-ferrous metal smelting industry: especially suitable for various acid solutions, corrosive slurries, slurries (for filter presses) and electrolytes in wet smelting of lead, zinc, gold, silver, copper, manganese, cobalt, rare earths, etc. , sewage and other media transportation.

3. Chemical industry and other enterprises: various sulfuric acid, hydrochloric acid, alkaline, oil clear liquid or slurry positions. Production of titanium dioxide and iron red powder, production of various dyes and pigments, non-metallic mineral processing and other industries.

4. Chlor-alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

5. Water treatment industry: pure water, high-purity water, sewage (leather sewage, electroplating sewage, electronic sewage, papermaking sewage, textile sewage, food sewage, domestic sewage, pharmaceutical industry sewage, etc.).

6. Iron and steel enterprises: sulfuric acid and hydrochloric acid stations in the pickling system, and sewage with impurities.

7. Wet/semi-dry desulfurization circulation pump: can be used in alkaline, acidic and corrosive positions at the same time.

8. Transportation of corrosive liquids and coal slurries in the coal industry and coal chemical industry; pumps for coal washing.

-

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86-15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP