SH(R)/SM(R)/SL(R)/SHH(R) Series Slurry Pump

Keyword:

Classification:

- Description

- Application

- Main Projects

- Technical Drawing

- Product Video

-

Product Specification

Size: 1" to 22"

Capacity: 3.6-5400 m3/h

Head: 6-125 m

Handing solids: 0-130mm

Concentration: 0%-70%

Materials: Hyper chrome alloy, Rubber, Polyurethane, Ceramic, Stainless steel etc.Product Description

★ The SH(R)/SM(R)/SL(R)/SHH(R) series of slurry pump is heavy-duty horizontal pump designed to handle highly abrasive, high-density slurries, offering excellent wear life and maintaining efficiency for the best total operating cost during the wear cycle.

★ The pump's shaft seal can be either a packing seal or a centrifugal seal. The pump outlet can be installed at eight different angles, at 45° intervals, as required.

★ The primary materials used for the overflow components include high chrome, rubber, polyurethane, and cramic

★ In order to accelerate the renewal of old centrifugal impurity pumps and expand the development of new products in order to provide reliable,durable,efficient and economical advanced products to all sectors of the national economy,the Company has introduced all centrifugal impurity pump licensing technologies.

★ Our centrifugal impurity pumps have the most advanced technology in the world and are sold all over the world and enjoy a high reputation internationally.The pumps are widely used,have an advance structure,a high degree of generalisation,reliable operation,a long service life and are easy to install and dismantle for maintenance.

★ In order to meet the long-distance transmission,it can be used in series with multiple stages according to special orders.

Performance Parameter

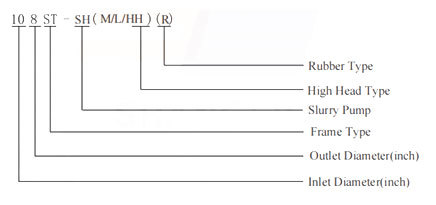

Model Meaning

Structure Description

The above various types of horizontal slurry pump except the pump head part(including pump body,pump cover,impeller,etc.)structure is different,the rest of the structure is similar,using the same series of transmission parts.The following describes the structural characteristics of the pump head,shaft seal and transmission parts respectively.

1、The Bare Shaft

The heavy duty slurry pump and the light duty slurry pump have a double casing structure,i.e.pump body and pump cover with replaceable wear resistant metal lining (including impellers,sheaths,shields etc.).The pump body and cover are made of grey cast iron or ductile iron according to the working pressure,vertically open and bolted together. The pump body is bolted to the bracket with a stop.The pump outlet can be rotated at eight angles.The impeller has a back vane on the front and rear cover to reduce leakage and increase the service life of the pump.The rubber lined pump is also of double casing construction with replaceable wear and corrosion resistant rubber liners(including impeller,front and rear sheaths)in the pump body and cover.The pump body and pump cover are common to the heavy duty slurry pump and the light duty slurry pump,and the transmission parts and mounting forms are also the same.

The gravel pump has a single casing structure(i.e.without liner).The pump body, pump cover and impeller are all made of wear-resistant metal.The pump body and pump cover are connected by a special clamping structure and the pump outlet can be rotated in any direction for easy installation and dismantling.

The inlet of each type of pump is horizontal and the pump rotates clockwise from the direction of transmission.

2、Sealing Parts

There are 3 Seal Types:Expeller seal,Packing seal and mechanical seal.(1)Expeller seal:When the positive pressure value of pump inlet is not greater than 10%of the pump outlet pressure value,single-stage pump or multi-stage tandem first-stage pump,the Expeller seal can be used.

(2)Packing seal:Packing seal is simple in structure and convenient in maintenance. However,shaft seal water must be used.For the working condition which is not suitable for shaft seal,the packing shaft seal can be used.

(3)Compared to the packing seal and expeller seal,the mechanical seal is better,in a longer cycle of operation,the seal state is stable and the leakage is small.

3.Drive Connection

All kinds of horizontal slurry pumps use the same series of transmission parts,including brackets and bearing assemblies,pump shaft diameter,good rigidity, short cantilever,in the harsh working conditions will not bend and vibration, bearing according to the different power transmission choose heavy single row or double row garden tapered roller bearings and garden column roller bearings,can withstand the maximum axial and radial load of the pump,bearings using grease lubrication,bearing body ends with sealing end caps,labyrinth sleeve and labyrinth ring,can effectively prevent slurry and other dirt into the bearings,to ensure that the bearings can be safe operation,with a hiah life.

Pump Dimision

Connection Method

Connection Method Spare Parts

Spare Parts

-

Slurry pumps can be widely used in mining, electric power, metallurgy, coal, environmental protection and other industries to transport mud containing abrasive solid particles. Such as slurry transportation in metallurgical dressing plants, hydraulic ash removal in thermal power plants, coal slurry and heavy medium transportation in coal washing plants, dredging of rivers, dredging of rivers, etc. In the chemical industry, some corrosive slurries containing crystals can also be transported.

Among the applications in mineral processing plants, about 80% are used in mineral processing plants.

In the power industry, mainly thermal power plants.

In the coal washing industry, due to different working conditions, larger coal blocks and easy blockage of coal gangue, the design requirements for slurry pumps are very high.

-

-

-

Related Products

Inquiry

SHANGLISHI PUMP GROUP

Department Director: Ms. Wang

Tel: +86-311-82725800/82725629

Email: admin@sls-pump.com

WhatsApp: +86-15830676372

Mobile Website

Mobile Website

Copyright © 2022 SHANGLISHI PUMP GROUP